Molded Pulp

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Printing Machines

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Molded Pulp | Certification | - |

|---|---|---|---|

| Category | Printing Machines | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

The company produces disposable food package with environment friendly materials to replace the plastic disposable package or bowl, which is the main cause of environment contamination. The company also produces facilities and products which are used for buffing materials and package.

Appearance

The package can be made in any shape and precision which are required with the advanced molding technology and high-temperature press. No deformation is guaranteed.

Surface

The surface is very soft and smooth so that excellent printing and machine absorption can be possible. It also enhances automation rate.

Function

New pulp, recycled paper pulp, and paper fiber based film, leather and fiber galss can be made into pulp by using Dongjin's advanced technology. It is also possible to design technical items such as water-resistance and conductivity, and strength.

Environment

Dongjin's compounding technology is to recycle the waste resources which might be scrapped or burnt. The waste can be treated either recycling, disposition (bio-decomposition) and burning (retrieval of energy) depending on the situations and there is no pollution problem with Dongjin's advanced technology.

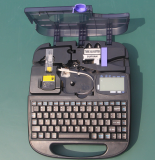

Model Name |

DPF-70/85 S2 |

|

Machine Q'ty / Line |

3 units (2~6 units) / Line |

|

Mold Base Size |

70 x 85cm |

|

Molding Method |

Upper Dumping of Constant Volume |

|

Operation Type |

Vertical |

|

Drying Method |

1.5 Step Drying |

|

Cycle Time |

35±5 sec |

|

Pulp Consumption (per hour) |

about 50~70 kg/unit (Lunch Box) |

|

Installation Area |

W15 x L20 m |

|

El. Power consumption |

400kW x 3P |

|

Required Workers |

4 workers/2 shift |

|

Trimming Worker(Option) |

0.5 worker |

|

Coating Workers(Option) |

1 worker |

|

Special Features |

① 2 step Forming & Drying system ② Cheap Mold Costs ③ For many kinds of small amounts / mass production ④ Hydraulic or Pneumatic cylinder |

|

Production

Amount (per hour) |

Rec. Tray

(140 x 180) |

12 Cavity x 100 cycle= 1,200

trays/unit |

Lunch Box

(175 x 230) |

8 Cavity x 100 cycle= 800

trays/unit |

|

Dishes

(φ200) |

15 Cavity x 100 cycle= 1,500

trays/unit |

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |