KM-3000(Emulsified Oil)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Feed Additives

Kwangil Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | KM-3000(Emulsified Oil) | Certification | - |

|---|---|---|---|

| Category | Feed Additives | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

KM-300(Emulsified Oil)

Characteristics

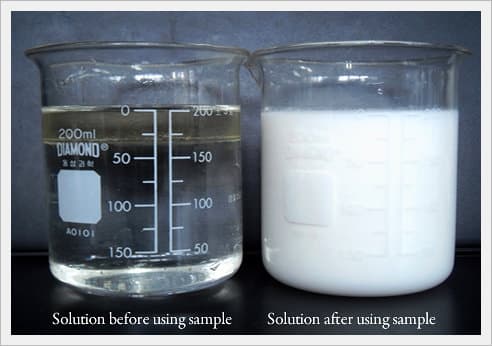

This product is widely used in the wheat flour products.

It is a emulsified oils of O/W type (the condition where the oil is dispersed to water soluble ingredient) that emulsion by using Lecithin,

natural emulsifying agent on the soluble ingredient for vegetable oil.

It strives the convenience of user by removing the difficulties such as purchasing the raw materials such as oil, emulsifying agent and others

and necessitates the emulsion facility. The oil is added to grant various function in processing foods and in that case this is a product which is convenient

Ingredients

D-Sorbitol Solution, Soybean Oil, Lecithin, Glycerin Esters of Fatty Acids

Specification

|

Appearance

|

Fresh Yellow and Fluid Paste

|

|

Arsenic(As)

|

Not more than 1.5ppm

|

|

Heavy Metal

|

Not more than 10ppm

|

|

Moisture

|

Not more than 20%

|

|

Acid Value

|

Not more than 3

|

|

Crude Fat

|

35%~40%

|

Packing Unit : 18kg tin can with carton box

Shelf Life : One year at the cool and dark place.

How to use and effect(when using the wheat flour on emulsified oil)

- The kneading and ripening time is shortened and the noodle formation is smoothly made.

- The oil is added to have a good shape with a fine adhesion prevention effect to enhance the production work efficiency.

- The moisture protection gets better in noodle making, bread making and cookie making and has the effect of preventing aging.

- It has an effect of shortening of micelle time of starch to shorten the cooking time slightly.

- The processing of product is much improved.

- When oil frying, it prevents spattering and has an effect in improving the oil frying product with a little oil absorption volume.

Dosage

- When making dumpling, add 0.9 ~ 1.5% (in comparison to the wheat weigh) of this product to the flour dough for dumpling skin, then the productivity is

significantly improved when forming of dumplings products. - When the ramen of Chinese type is produced, add 1.5 ~ 2.0% of flour dough for producing the ramen production to make fine formation of dough from the roller,

and it improves the joint formation to heighten the production efficiency, and make the great shape of noodle. - When the soybean milk is produced and processed, add this product for 2~3% to make the savory taste of soybean milk and it increase the quality and

preference of product. - When bread dough is made, add 1.5~2.0% to have high kneading efficiency to shorten the kneading time and increase the different shape of bread and shorten

the cooking time as well. - It is even more convenient in using for emulsion type beverage that the emulsion type beverage of cloudiness can be processed by added and stirred

for the desired volume. There is no need for processing for a separate emulsion. - When the food is produced and processed, it is convenient to use by adding appropriate volume for the purpose of enhancing the fat & oil contents.

- This product is made with the soybean oil for fat & oil material when producing, but it can emulsify and supply for unsaturated edible oil such as palm oil, coconut oil, sesame oil, rapeseed oil, corn oil and others depending on the needs.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- LEE, MAN-YOUNG

- Address

- 112-2, Hangangno 2-ga, Yongsan-guSeoul,

- Product Category

- Feed Additives

- Company introduction

-

Our company was founded in 1966 with the aim to contribute to the food industry of Korea by developing quality food materials. Since then, it has produced a range of food additives including glycerine fatty acid ester, the company's first product, and dedicated itself to investment to R&D activities in order to produce better products than those imported, providing them at cheaper prices. Thanks to such dedication and the technology achieved from it, the company is now leading the market.

In 1970, the company moved its main plant to Shinjong-dong of Youngdungpo-gu, Seoul, and continued to grow. It expanded and moved its main plant again In 1979 to Asan of Chungnam Province, expanding its range of products to calcium sulfate, calcium carbonate, emulsifiers, powder flavorings and soy bean protein products. It has now become an integrated food manufacturer producing a total of more than 110 items of product including food additives, seasoning products, cereal products, and a lot more.

Already a leading company in the market, it supplies as much as 5,000 tons of products a year for the food industries at home and abroad. As in most areas in the modern society, the food industry is also going through rapid changes in technology and the business environment. Based upon the knowledge and the wonderful performance achieved for the last 34 years, the company will continue to dedicate all its energy and resources to develop and manufacture better products that fully meet the needs of our customers worldwide. Our goal is making a meaningful contribution to the healthy eating life of people.

- Main Markets

-

China

China

Indonesia

Indonesia

Philippines

Philippines

Taiwan

Taiwan

Thailand

Thailand

- Factory Information

-

Kwangil co.,ltd

- Main Product

Related Products

PROBION-forte

COLLAGEN 'P' COLLAGEN PEPTIDE VITAMIN-C FISH COLLAGEN

FCC food grade calcium sulfate dihydrate

E516 food grade calcium sulfate anhydrous

SOMA-MEAT T