Electro-coloring Rectifier

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Electrical Equipment

KooSoo Heavy Electric Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Electro-coloring Rectifier | Certification | - |

|---|---|---|---|

| Category | Electrical Equipment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

1) Summary

- Although the coloring of aluminum can be divided into a few groups according to the coloring chemicals used, this is an explanation of the alternating power equipment for the most standard method of construction being the SN mixture and Ni separately and also the widely used soluble additives of other substances including boric acid.

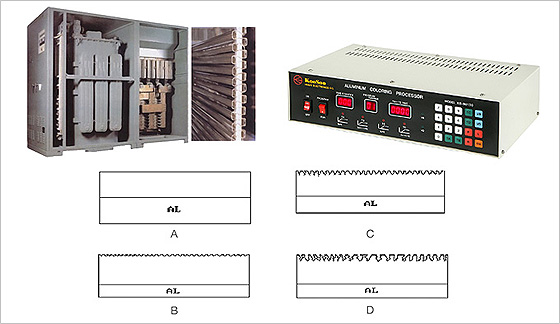

The picture above shows the change in the aluminum surface due to anodizing. In the order of A⇒B⇒C⇒D, it shows the change in the aluminum surface due to anodizing into one that has a hard barrier surface.

The construction of the surface is formed in the film thickness appearance as shown in picture "D". As the film thickness is raised, the depth of the surface increases. Alternating coloring is achieved through infusing ions on the surface which is gained through the film allowing for the desired color.

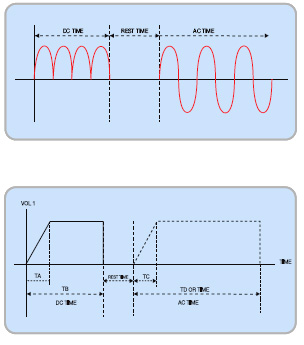

2) Output waveform

|

On the inside of the porous layer of the aluminum surface, after anodic oxidation of the film, a sulfuric ion from electrolyte components remains and the film on the porous layer remains with uneven depths. As a result, by allowing a flow of direct current, a path for the current to flow smoothly within the machine is provided together constructing the inside of the porous layer with an even depth. A direct current is circulated as a preparation process for alternating current coloring and around 40~60 seconds of discontinuation time is given terminating the electrochemical operation generated within the surface interior. Next, circulate the alternating current and coloring process takes place with the color being controlled according to the alternating current circulation time. Automation is possible due to the Micro Processor which was developed by our company and designed to maintain the manufacturing of an even color tone.

TA-TB-TC-TD-VB-VD etc has a timer function. A maximum of 89 types of programs are able to be input with a memory of 24 hours in case of blackout. TA and TC Minimum TIME 30 Sec (Min) |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Won Gu, Kim

- Address

- #708 3-Na, Shihwa Industrial Complex, 14, Gongdan 1-daero 259beon-gil, Siheung-si, Gyeonggi-do, KOREA

- Product Category

- Electrical Equipment,Other Machinery & Industry Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

At KooSoo Heavy Electric Co., Ltd., we engage in the manufacture of rectifiers. Since our founding in l984, we have been devoted to the enhancement of competitive capabilities through the development of technology and the innovation of quality. At present we are making every endeavor to take the lead in the business world of rectifiers for the surface treatment with incessant research and development.

Up to the present, we have developed a wide range of products: IGBT RECTIFIER. SCR RECTIFIER and PLASMA BIPOLAR RECTIFIER. As regards IGBT, a nation-wide innovation, it claims to be the Third Generation Rectifier. So far we have depended on imported products for surface treatment.

For SCR Rectifiers, we manufactured 50V 70000A, the largest nation-wide capacity. Furthermore, we have developed a PLASMA BIPOLAR RECTIFIER in coordination with Seung Guin Kwan University. Now we can claim to be the de facto first runner of this business world.

- Main Product

Related Products

EM-30

Fused silica glass, quartz glass, JGS1, JGS2, JGS3

Antistatic Earthing Touch Pad / Discharge electrostic Pad

_2.jpg)

Group Starter Panel (GSP)

Immunoactivating Micro Bubble Generator