Steam Sterilizer (CS-ST045, ST065)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Water Treatment

JW Medical Corporation Co., Ltd.

- Verified Certificate

-

17

| Product name | Steam Sterilizer (CS-ST045, ST065) | Certification | - |

|---|---|---|---|

| Category | Water Treatment | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Heater Compartment

With a separate heater compartment at the bottom of the chamber, the sterilizer not only has a larger capacity than other products, but also utilizes less water for sterilization. The design minimizes heating time and greatly improves drying performance.

Air Evacuation after Water Supply

The method of vacuum drying after water is supplied to the chamber differs from existing processes in that all air in the chamber is removed completely with a vacuum pump before water is added, to assure 100% sterilization. The conventioanl water supply method allows a considerable volume of air on the objects of sterilization, so that a through and complete sterilization is not guaranteed. Certain spores in an air layer may not be completely removed. The Air Evaporation Method reduces the evaporation point of the water and forcibly releases all the air in the objects to be sterilized, guaranteering perfect sterilization results with quick heating and steam penetration.

Appealing Design

The products is beautifully designed for a refined appearance and harmonious integration in a hospital environment.

Quick Water Supply

By supplying water directly into a vacuum, the filling time is sharply reduced (20 seconds at most) and the product is usable continously at high temperatures. It supplies water faster than with conventional methods.

Fully automated Control

The whole process of sterilization, from vacuum sterilization to vacuum drying is electronically controlled and fully automatic. Once the sterilization program is set, only press START and the complete process of Vacuum Build-up → Water Supply → Heating → Sterilization → Air Release → Vacuum Drying takes place automatically.

Recorder Installation

The printer records sterilization conditions (date, temperature, time and drying time, etc.) under normal operation.

Self-diagnosis

A total of 13 error conditions are displayed under the self-diagnostic control. Your Safety is our top Priority!

This steam sterilizer is designed for user's convenience and patient's safety preferentially.

Self-diagnosis:

| A total of 13 error conditions are displayed under the self-diagnostic control. | ||

|

ERROR-1

|

Water tank low |

|

|

ERROR-2

|

Heater overheated (Standard throughout the process : 155°C, Dry : 190°C | |

|

ERROR-3

|

Door open during operation | |

|

ERROR-4

|

Sterilization temperature deviations | |

|

ERROR-5

|

Short water supply | |

|

ERROR-6

|

Heating time exceeded | |

|

ERROR-7

|

Temperature sensor error(Disconnection/Short circuit) | |

|

ERROR-8

|

Heater temperature sensor error(Disconnection/Short circuit) | |

|

ERROR-9

|

Pressure sensor error(Disconnection/Short circuit) | |

|

ERROR-10

|

Vacuum release test failure | |

|

ERROR-11

|

Vacuum lead time excess setting | |

|

ERROR-12

|

Chamber overheated during water supply | |

|

ERROR-13

|

Chamber pressure exceeded (2.4kgf/cm2) | |

LCD Display :

On the control part, both the LCD display and FND display the steps of the sterilization process. The displays are large and easily visible, even from a distance. The LCD displays sterilzation temperature, pressure, lead time, drying temperature and time, heater compartment temperature, water tank level, and door open/close status, so that the user can monitor the equipment fully at any time.

Sterilization Programs :

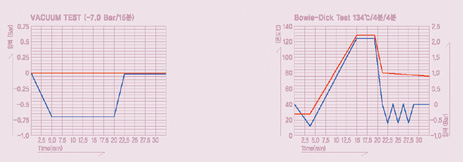

The test program mode is the most convenient to use. With the Bowie-Dick test, a special program to check sterilizer performance on a regular basis, the efficiency and reliability of the equipment is maintained. The VACUUM LEAKAGE TEST shows any leaks in the sterilizer, so that the user can determine firsthand whether the product has a problem.

| Basic program | ||||

|

Pack

|

Instrument

|

Glove

|

Liquid

|

|

|

Termperature

|

134°C

|

134°C

|

121°C

|

131°C

|

|

Pressure

|

2kgf/cm2

|

2kgf/cm2

|

1kgf/cm2

|

1kgf/cm2

|

|

Time

|

20min

|

10min

|

30min

|

30min

|

|

Dry Time

|

30min

|

20min

|

20min

|

-

|

| User program | ||

|

Manual program

|

Dry program

|

|

|

Termperature

|

121°C~134°C

|

-

|

|

Pressure

|

1kgf/cm2 ~ 2kgf/cm2

|

-

|

|

Time

|

0~60min

|

-

|

|

Dry Time

|

0~60min

|

0~60min

|

| Test program | ||

|

Vacuum leakage test

|

Bowie-dick test

|

|

|

Termperature

|

Normal temperature

|

134°C

|

|

Pressure

|

0kgf/cm2

|

2kgf/cm2

|

|

Time

|

15min

|

4min

|

|

Dry Time

|

-

|

4min

|

Specifications

|

Model

|

CHS-ST045

|

CHS-ST065

|

|

|

Overall Site

|

580(W) x 510(H) x 650(L)mm

|

580(W) x 510(H) x 820(L)mm

|

|

|

Chamber

|

Size

|

310(W) x 340(H) x 430(L)mm

|

310(W) x 340(H) x 620(L)mm

|

|

Type

|

Square

|

||

|

Material

|

KS D 3577-85(STS316)

|

||

|

Capacity

|

45Liter

|

65Liter

|

|

|

Sterilizer Temperature, Pressure

|

121°C(1kgf/cm2) ~ 134°C(1kgf/cm2)

|

||

|

Reservoir Capacity

|

6.0Liter

|

8.0Liter

|

|

|

Heater

|

2.3KW

|

2.9KW

|

|

|

Power Source

|

AC220V 50/60Hz 2.3W

|

AC220V 50/60Hz 2.9W

|

|

|

Air Removal

|

Oil-less vacuum pump(40 RNS)

|

Oil-less vacuum pump(50 RNS)

|

|

|

Display

|

Graphic LCD

|

||

|

Control Mode

|

Micro processor

|

||

|

Recorder

|

Dot Printer

|

||

|

Dry System

|

Vacuum dry system

|

||

|

Weight

|

93kg

|

110kg

|

|

Option Accessory

|

Cart

|

CHS-ST045

|

620(W) x 820(H) x 560(L)mm

|

|

CHS-ST065

|

620(W) x 820(H) x 750(L)mm

|

|

|

Printer

|

Dot Printer

|

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- NOH YONGKAP

- Address

- 2477, Nambusunhwan-ro, Seocho-gu, Seoul, Republic of Korea

- Product Category

- Other Health Care Products

- Year Established

- 1972

- No. of Total Employees

- 101-500

- Company introduction

-

Founded in 1972, JW Medical has established itself as a key player in Korea’s local medical market. We manufacture cutting edge proprietary products, and locally supply carefully selected imported products from reputable international companies.Through a process of continuous investment in new technology and expert consultation, we concentrate our efforts on the local production of advanced medical equipment such as Infant Incubators, LED Phototherapy Unit, Operating Table, LED Surgical Light, Digital X-ray, Gynecological tables and sterilizers. Our research and investment has extended into biochemistry, and we have created a range of immuno-chemical and molecular diagnostic reagents which provide cost-effective accurate results and are now internationally exported.JW Medical is positioned to enter the international marketplace. Our global strategy incorporates the best practices in customer service, product development, work-place safety and employee involvement.

- Main Product

South Korea

South Korea

_2.png)