SCR (Selective Catalytic Reduction)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Catalyst & Chemical Auxiliaries

Nano Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | SCR (Selective Catalytic Reduction) | Certification | - |

|---|---|---|---|

| Category | Catalyst & Chemical Auxiliaries | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

De-NOx SCR catalyst removes the NOx contained in exhaust gases discharging from power plants, industrial boilers, ships, incinerators, chemical plants and diesel automobiles etc.

SCR Catalyst

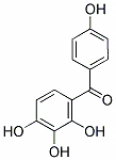

SCR (Selective catalytic reduction) is a typical De-NOx technology which deoxidizes NOx to Nitrogen on the surface of catalyst. Ammonia and Urea are used for reductant and then NOx is reduced to Nitrogen and water at lower temperature due to the SCR catalyst. This technology has been widely used in industrial facility since it showed a high reduction rate of NOx up to 90%.

SCR Reaction Mechanism

Comparison of De-NOx Technology

|

Technology

|

SCR

|

SNCR

|

Low Nox Burner

|

|

Outline

|

- Inject NH3 to the catalyst - reduce NOx |

- Inject UREA/NH3 - NOx reduction without catalyst |

- Combustion method - Lower oxygen concentration and flame temperature |

|

NOx removal rate

|

70~90%

|

25~50%

|

30~50%

|

|

Investment

|

High

|

Low

|

Medium

|

|

Operation Expense

|

Medium

|

High

|

Low

|

|

Consideration

|

- Installallation space - Catalyst removal and replacement |

- Stucture of combustion furnace - Residence time of reductant |

- Fan capacity - Stability of flame |

|

Overall Evaluation

|

- Applied to medium & large facility | - Restrict the operation condition - Existing customer unsatifaction factors |

- Suitable for small facility - Existing the limited NOx removal rate |

Comparison of air regulation invarious countries

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- SHIN, DONG-WO

- Address

- 1188 Magong-ri, Cheongri-myeon, Sangjoo-si, Gyeongsangbuk-do, 660-882, Korea

- Product Category

- Other Vehicle Accessories

- No. of Total Employees

- 1-50

- Company introduction

-

Welcome to the ceramic specialty company. NANO is consistently pursuing leading company in ceramic raw material powder and extrusion products. We established a mass production line for nanoscale photocatalytic powder at the end of 2001. The new low-cost processing technology was certified by Ministry of Commerce, Korea, in July 2001. In addition, the pilot-plants for WS2 solid lubricant powder and ceramic honeycomb catalyst were also successfully completed in the early of 2001 after more than 3 years of intensive R&D. We will thus complete large-scale ceramic honeycomb production line in the middle of 2002.

Based on the our initial products of photocatalytic TiO2 and WS2 lubricants, we diversify our powder products for IT ceramic parts and ET ceramic honeycomb using our raw materials. Various applications of our raw materials such as self cleaning building materials and air purifying system will be presently shown in the market. NANO's key organization is R&D center consisting of 3 teams depending on the aimed processing , i.e., Raw Materials, Extrusion and Application. Our R&D activities mainly focus on developing the new low-cost processing.

I again appreciate you for your visit to NANO homepage. Your suggestions will be promptly responded.

- Main Product