Fix Chamber Round Baler -Medium Size

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- baler, round baler

- Category

- Balers

Myungsung Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | Fix Chamber Round Baler -Medium Size | Certification | - |

|---|---|---|---|

| Category | Balers | Ingredients | - |

| Keyword | baler , round baler | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Different Intake Systems

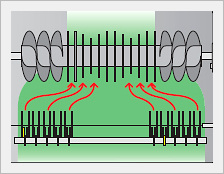

Integral Rotor Technology

| Large diameter, heavy duty auger flying is integrated directly onto the outer sections of the rotor, which is called integral Rotor Technology. This simple, maintenance-free, short-distance intake system ensures even feeding regardless of variations in the crop. With this system, even the heaviest of crops are force-fed through the hort intake, resulting in higher forward speeds for outstanding productivity and less crop damage. |

|

Opticut 5

| This Integral Rotor incorporates a 5-knife OptiCut system designed to even out the windrows and forcefeed the crop into the baler for maximum throughput. The 5-knife OptiCut cutting system provides a theoretical cutting length of 180mm. Each single knife is spring protected against damage from foreign objects. The knives and scrapers overlap across the intake area to ensure maximum efficiency. |  |

* The all new rotor design allows more room for the crop and more efficient direction of the crop over a longer cutting surface.

This result in a more effective cut and less horsepower required, as well as less chance for rotor blockage.

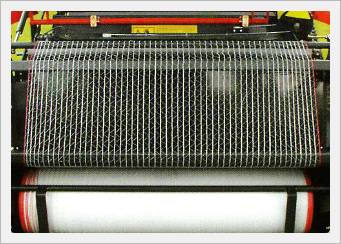

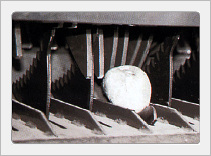

Bale Chamber

| Producing many silage, hay and straw bales each season and extremely tough and well thought-out design is demanded. In addition to compressing the crop into consistent size and dense bales, the baling process has to be as effective as possible, while being gentle on the crop. With 16 Bale Truck rollers, equipped with a unique ribbed profile for optimum traction and compression. |  |

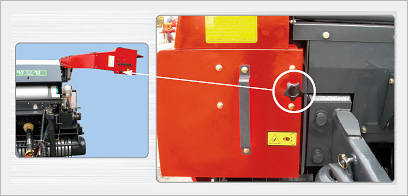

Excellent Open

|

A spherical shape & onet ouch open side cover means, daily maintenance is shorter and easier. |

|

Dropfloor

The complete cutting floor including the knives can be lowered hydraulically from the driver's seat. First the cutting floor will be lowered followed by the knives. After the blockage is cleared the cutting floor including the knives can be brought back into working position.

|

|

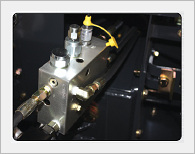

| Driveline The machine is fitted with heavy-duty drive chains. Which ensure long life and minimum down time. |

PowerLock Strong, rear door hydraulic cylinders work in combination with a hydraulic lock valve to produce maximum bale density. The accumulator levels off peak loads on the rear door. Those who needs diverse bale densities the pressure manually can be set up to a maximum of 120 bar. |

Excellent Intake Performance

|

Net binding Net binding system is minimum loss of crops, efficient binding works with automatic binding system. |

| Knife Protection Knives are protected by springs any obstruction deflects knives individually, which is automatically return to the cutting position when obstruction was passed. |

|

|

Easy Plus The in-cap control box provides clear and easy to read information and gives full command of the baling process. An audible and visual alarm signals when the bale is ready. A choice in automatic or manual start of the tying process can be preselected. Adjustments like the number of net wrap are easily controlled with seating in a tractor. Easy Plus also provides a daily and total bale counter. With the integral magnet and hook on the backside, the control box easily can be installed in each tractor cab without any tools. |

Options

|

|

|

|

|

Different wheel sizes

|

2 Point Link

|

Chain oiler

|

Fermentation Tank

|

Specification

|

Model

|

RB1000DF

|

|

|

Dimensions

|

Width (m)

|

3.39

|

|

Height (m)

|

2.0

|

|

|

Length (m)

|

2.0

|

|

|

Weight (kg)

|

2,340

|

|

|

Pickup

|

Pickup width (m)

|

1.8

|

|

Number of tine rows

|

4

|

|

|

Intake

|

Integral Rotor

|

OptiCut 5

|

|

Knives

|

5

|

|

|

Cutting length (mm)

|

180

|

|

|

Knife protection

|

Single / Spring

|

|

|

Bale Chamber

|

Diameter (m)

|

1.0

|

|

Width (m)

|

1.0

|

|

|

Bale formation

|

16 rollers

|

|

|

Roller diameter (mm)

|

100

|

|

|

Automatic chain oiler

|

Standard

|

|

|

Net binding / storage

|

Standard / 1 roll

|

|

|

Operation

|

Control system

|

EasyPlus

|

|

Tyres

|

11.5/80-15.3

|

Standard

|

|

15.0/55-17

|

Optional

|

|

|

Other

|

Min. power requirement (kw/hp)

|

37/50

|

|

Fermentation Tank (option)

|

50 L

|

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Inhyun Lee

- Address

- 88 Palyongdang-gil, Pyeongtaek-siGyeonggi-do,

- Product Category

- Farm Machinery

- No. of Total Employees

- 1-50

- Company introduction

-

MYUNGSUNG Co., Ltd. Is a manufacturer of hay and silage making machinery such as baler, bale wrapper, manure spreader and etc. in Korea.

Since established in 1982, we have been trying to do our best to be a leading supplier and manufacturer oflivestock machinery in Korea not only by introducing the high-quality products from advanced livestock countries, but also by developing all of those machinery to supply the most competent products to our domestic farmers.

With the establishment of R&D institute in 2007 and through continuous investment in producing home-made livestock machines suitable to Korean geographical features and crops, thus leading the domestic market and also could export some of the machines to overseas countries such as Japan and India.

We're always making our best efforts to meet the desired customer's demand base on highly advanced technology. If you have any information required, please feel to contact us.Thank you!

- Main Product

Related Products

Coconut fibre baling press

Mid-size Round Baler (L310)

Baling Machine

square baler

Coconut Fibre Screener