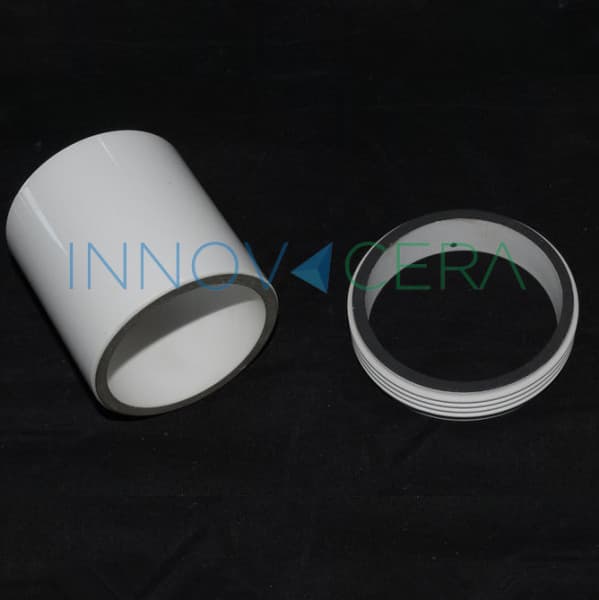

High purity Al2O3 metallized ceramic Insulator

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- INNOVACERA

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- al2o3 metallized, al2o3 metallized ceramic, metallized ceramic insulator, metallized ceramic tube

- Category

- Ceramics

Xiamen Innovacera Advanced Material Co.,Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

13

| Product name | High purity Al2O3 metallized ceramic Insulator | Certification | - |

|---|---|---|---|

| Category | Ceramics | Ingredients | - |

| Keyword | al2o3 metallized , al2o3 metallized ceramic , metallized ceramic insulator , metallized ceramic tube | Unit Size | - |

| Brand name | INNOVACERA | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Welcome to contact me for more detailed information:

Chandler Tsai - chandler(at)innovacera(dot)com

High purity Al2O3 metallized ceramic Insulator, electrical ceramic insulators, vacuum ceramic insulation

1. Advanced ceramics - Change the world!

- low density

- high hardness

- high mechanical strength

- dimensional stability (specific stiffness)

- resistance to wear

- resistance to corrosion (resistance to chemical attack)

- weathering resistance

- high working temperature

- low or high thermal conductivity

- good electrical insulation

- dielectric and ferroelectric properties

High purity Al2O3 metallized ceramic Insulator, electrical ceramic insulators, vacuum ceramic insulation

2. Applications and joining types:

| Applications: | |

| Feed-through insulators | Power switches |

| Insulating discs | Traveling wave tubes |

| Insulator rings and cylinders | Vacuum interrupters |

| Headers | Windows |

| High-power receptacles | Power grid tubes |

| Precipitator products | X-ray tubes |

| Joining types: | |

| Ceramic + Mo/Mn Metallized + plating Ni | |

| Ceramic + Mo/Mn Metallized + plating Ag | |

| Ceramic + Mo/Mn Metallized + plating Au | |

| Ceramic + printing Ag | |

| * Special types are available according to customer's drawings or samples. |

3. More about us:

Innovacera can supply many kinds of ceramic parts according to the customers' differents requirements. Our products include the ceramic plunger, ceramic plunger pump, ceramic rod, ceramic shaft, ceramic piston, ceramic water valve sheet, ceramic pipe sleeve, ceramic loom plunger, ceramic seal ring, special shape ceramic, ceramic knife etc.

Our own factory: located in Zhangzhou, Fujian - one hour drive from Xiamen

Certifications: ISO 9001-2008, ISO14001-2004, OHSAS 18001-1999

Export office: located in the Special Economic Zone - Xiamen

Other popular products: Tubes, Balls, Honeycomb, Seals, Beads, Substrates, Rollers etc.

Welcome to visit us, if you have any demand or inquiry, please feel free to contact us!

High purity Al2O3 metallized ceramic Insulator, electrical ceramic insulators, vacuum ceramic insulation

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

Xiamen Innovacera Advanced Material Co.,Ltd

- Country / Year Established

-

China

/

China

/

- Business type

- Others

-

13

- President

- Qiu

- Address

- RM615, No.398 Jiahe Road, Huli District, Xiamen

- Product Category

- Ceramics,Industrial Supplies,Machinery & Parts

- No. of Total Employees

- 51-100

- Company introduction

-

Chandler Tsai - chandler(at)innovacera(dot)com

Chandler Tsai - chandler(at)innovacera(dot)com

Chandler Tsai - chandler(at)innovacera(dot)com

Chandler Tsai - chandler(at)innovacera(dot)com

Innovacera is a leading manufacturer of advanced ceramic products from China. We supply quality technical ceramic materials and components with competitive price.Our fine ceramics were exported to Europe, North America, Japan, South Korea, Australia, the quality is creditable.Our available materials for sale are: high purity alumina(Al2O3), zirconia(ZrO2), Silicon Carbide, Silicon Nitride, Boron Nitride, steatite, metalized ceramics etc.Our general ceramic parts include: ceramic tube, ceramic rod, ceramic plate, ceramic disc valve, ceramic wafer, ceramic seal, ceramic bearing, ceramic valves, ceramic pump plunger, ceramic beam, ceramic roller, ceramic shaft, ceramic screw, ceramic sleeve, ceramic washer, ceramic lamp holder, ceramic insulator, ceramic nozzle, ceramic lining, ceramic guide, ceramic grinding media, ceramic milling ball or beads.These precision tolerance ceramic components or assemblies are used in a wide range of semiconductor, electronic, electrical, mechanical, chemical, automotive, textile and the other industrial engineering applications, due to their extreme hardness, more resistances to wear, heat, corrosion, high eclectric insulation and low thermal expansion.We offer custom service, free quotes, and quantity discount, please feel free to contact us to get our best offer!

- Main Markets

-

Canada

Canada

Germany

Germany

Israel

Israel

Italy

Italy

Russia

Russia

South Korea

South Korea

U.S.A

U.S.A

- Main Product

Related Products

Zinc oxide (ZnO) ceramic target

Pyrolytic Boron Nitride Tube For Vacuum Furnace/INNOVACERA

Ceramic Fiber Blanket

WP-13028-A - Hand Woven Planters - Set of 2 ceramic pots with rattan and seagrass weaving

Wear & Corrosion Resistant Si3N4 Silicon Nitride Ceramic Bar