PE Wax (Polyethylene Wax)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Catalyst & Chemical Auxiliaries

SFC Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | PE Wax (Polyethylene Wax) | Certification | - |

|---|---|---|---|

| Category | Catalyst & Chemical Auxiliaries | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

1-1. Alkyl Dimethyl Benzyl Ammonium chlorides

|

Product Name

|

Alkyl Group

|

Application

|

|

Non-emulsion

Types |

L-518

L-533 L-540 |

Pigment dispersing agent for plastic high concentrate (master batch), External lubricant for PVC extrusion processing, Wear resistance improver of paints and inks, Engineering plastic lubricants, Hot-melt processability improver, paper coating agent, rubber processability improver, Improver of various waxes' fusion point. |

|

H-633

H-640 |

Dispersing agent of PS retardants and plastic pigment concentrates (master batch), Wear resistance improver of paints and inks, Engineering plastic lubricants, Hot-melt processability improver, paper coating agent, EPS nucleating agent, Improver of various waxes' fusion point. | |

|

LH-1200

|

Pigment dispersing agent for high concentrate (master batch) | |

|

LH-400

HCF-440 |

Jelly compounds for cables | |

|

HLP-300P

HLP-300F |

PVC internal lubricants, Calpeat processing agents, Hot-melt processing agents Pigment dispersing agent, for plastic pigment concentrates (master batch), Improver of various waxes' fusion point, PVC internal lubricants, Wear resistance improver of paint improver for road signal | |

|

Emulsion

Types |

LE-718

LE-705 |

Fabric softners, floor varnishes, PVC extrusion processing internal lubricants Protector of paint sedimentation. |

1-2. Homo-Polymers

|

Item

|

Softening

Point (°C) |

Melt viscosity

(at 140°C, cPs) |

Density

(at 25°C), g/cm3) |

Penetration hardness

(0.1mm) |

Acid value

(mgKOH/g) |

Physical forms

|

|

L - 518

|

101±3

|

180±50

|

0.92±0.01

|

max 3.5

|

Nil

|

Power

|

|

L -533

|

106±3

|

300±100

|

0.92±0.01

|

max 3.5

|

Nil

|

Power

|

|

L - 540

|

107±3

|

400±100

|

0.92±0.01

|

max 3.0

|

Nil

|

Power

|

|

L -570

|

108±3

|

750±100

|

0.92±0.01

|

max 3.0

|

Nil

|

Power

|

|

L - 633

|

118±3

|

330±100

|

0.93±0.02

|

max 2.0

|

Nil

|

Power

|

|

H - 640

|

120±3

|

400±100

|

0.96±0.02

|

max 2.0

|

Nil

|

Power

|

|

LH - 1200

|

109±3

|

1,100±150

|

0.92±0.01

|

max 3.5

|

Nil

|

Power

|

|

LCF - 400

|

108±3

|

500±100

|

0.92±0.01

|

max 3.5

|

Nil

|

Power

|

|

HCF - 440

|

118±2

|

650±50

|

0.94±0.01

|

max 1.0

|

Nil

|

Power

|

|

HLP - 300P

|

110±10

|

50±20

|

0.94±0.01

|

max 9.0

|

Nil

|

Power

|

|

HLP - 300F

|

110±10

|

10 ~ 100

|

0.94±0.01

|

max 9.0

|

Nil

|

Flakes

|

1-3. Oxidized Homo-Polymers / Emulsifiable Type

|

Item

|

Softening

Point (°C) |

Melt viscosity

(at 140°C, cPs) |

Density

(at 25°C), g/cm3) |

Penetration hardness

(0.1mm) |

Acid value

(mgKOH/g) |

Physical forms

|

|

LE- 718

|

100 3

|

250 100

|

0.94±0.01

|

max 4.5

|

16±2

|

Power

|

|

LE- 705

|

110 10

|

50 20

|

0.94±0.01

|

max 6.5

|

16±2

|

Power

|

2-1. PP Wax (Polypropylene wax)

|

Product Name

|

Alkyl Group

|

Application

|

|

Non-emulsion

Types |

PH-820

PC-820 PH-810 PC-820 |

Pigment dispersing agent for high concentrate (master batch) Improver of hot-melt processability, Improver of grease fusion point |

|

Oxidization Types

|

PHE-920

PCE-903 |

Processability improver of hot-melt, Battery fillers |

2-2. Homo-Polymers

|

Item

|

Softening

Point (°C) |

Melt viscosity

(at 170°C, cPs) |

Density

(at 25°C), g/cm3) |

Penetration hardness

(0.1mm) |

Acid value

(mgKOH/g) |

Physical forms

|

|

PH-820

|

158±3

|

200±100

|

0.89±0.01

|

max 1.0

|

Nil

|

Power

|

|

PH-810

|

158±3

|

90±50

|

0.89±0.01

|

max 1.0

|

Nil

|

Power

|

2-3. Co-Polymers

|

Item

|

Softening

Point (°C) |

Melt viscosity

(at 140°C, cPs) |

Density

(at 25°C), g/cm3) |

Penetration hardness

(0.1mm) |

Acid value

(mgKOH/g) |

Physical forms

|

|

PC-820

|

148±3

|

200±100

|

0.89±0.01

|

max 1.0

|

Nil

|

Power

|

|

PC-810

|

148±3

|

90±50

|

0.89±0.01

|

max 1.0

|

Nil

|

Power

|

2-4. Oxidized Polypropylenes / Emalsifiable type

|

Item

|

Softening

Point (°C) |

Melt viscosity

(at 140°C, cPs) |

Density

(at 25°C), g/cm3) |

Penetration hardness

(0.1mm) |

Acid value

(mgKOH/g) |

Physical forms

|

|

PHE-920

|

158±3

|

200±50

|

0.89±0.01

|

max 1.0

|

4

|

Lumps

|

|

PCE-903

|

120±3

|

50±10

|

0.89±0.01

|

max 30

|

4

|

Lumps

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- JEONG-SUK LEE

- Address

- 2135 Hwadong-ri, Hwayang-myeon, Yeosu-si, Jeollanam-do, Korea

- Product Category

- Candles & Holders

- No. of Total Employees

- 1-50

- Company introduction

-

Since our establishment in 1998, starting as a surfactant manufacturing factory, we have dedicated ourselves to providing high quality products with competitive prices, therefore we could satisfy our customer's requirements. We have been continuously focusing on the development of products that are in tune with R&D efforts, modernization of production processes. In particular, our R&D activities have helped us secure leading positions in the production of surfactant.

-NONIONIC SUNFOL Series are in Nonionic surfactants which are belong in the Ethylene oxide lineage. These products have wonderful properties in emulsification, dispersion and pernetrating effects. The hydrophilic property is related with adducted ethylene oxide mole, and hydrophobic property is related with base materials. It can be control penetrating, cleaning, emulsifying dispersant and foaming effects by choice base materials. In general, EO adducted nonionic surfactants have good chemical resistance, and very stable in acid and alkali solution.

-General Application : Textile industry, Paper & Pulp industry, Agricultural chemicals, harmaceutical, Rubber industry, Paint, Resin, Metal industry.

- Main Markets

-

China

China

Indonesia

Indonesia

Turkey

Turkey

- Main Product

Related Products

Corn Cob Meal

VCI Desiccant GVD300

C9 Petroleum Resin for Tire Rubber Compound softening oil

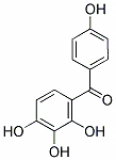

2,3,4,4'-Tetrehydroxybenzophenone, CAS NO.: 31127-54-5

VCI Desiccant GVD310