Non-metallic sludge scum collection system

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- Linkon sludge collector

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- collector, sludge, sludge collector, non metal

- Category

- Industrial Supplies , Water Treatment , Environmental Products , Waste Management

Linkon Technology.CO.,LTD

- Verified Certificate

-

14

| Product name | Non-metallic sludge scum collection system | Certification | - |

|---|---|---|---|

| Category |

Industrial Supplies

Water Treatment Environmental Products Waste Management |

Ingredients | - |

| Keyword | collector , sludge , sludge collector , non metal | Unit Size | - |

| Brand name | Linkon sludge collector | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Non-metallic sludge & scum collection system

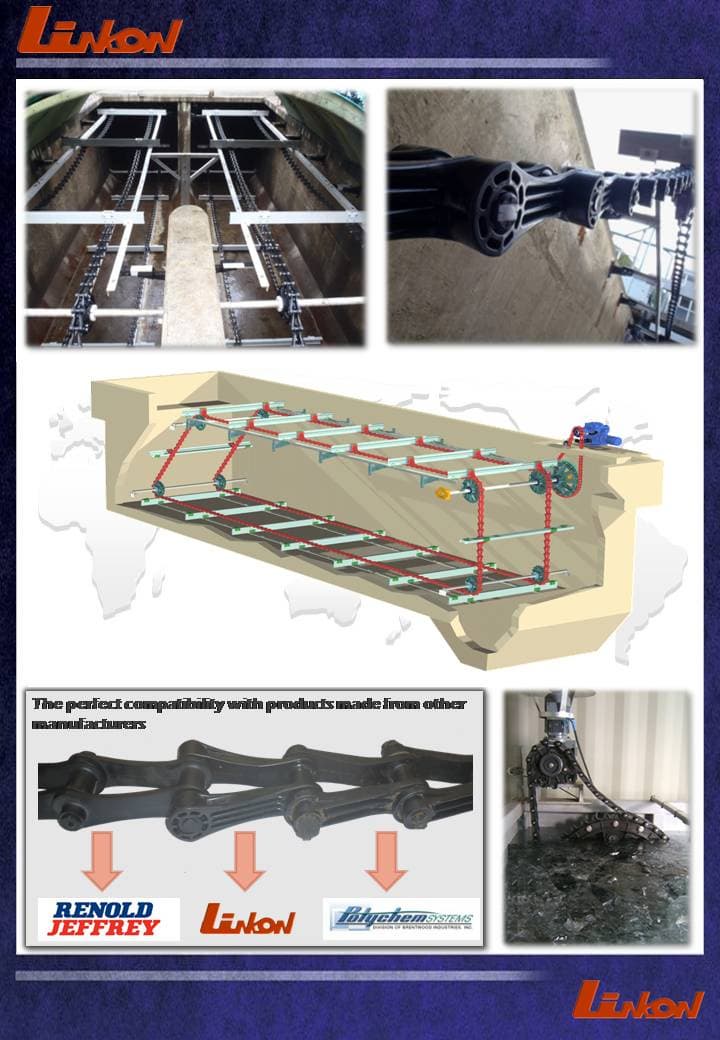

Linkon Technology’s non-metallic rectangular sludge collection system is a straight-line chain & flight/scraper sludge collecting mechanism. The purpose of this mechanism is to convey settled solids to one end of a structure(tank) in order that the resulting accumulated sludge can be removed from the tank by down-stream processes. This non-metallic collector mechanism consists of motor/gear reducer transmitting torque NH-78 non metallic drive chain and sprockets to the head shaft of the collector mechanism. The collector rotates through a series of sprockets, NCS720S chain, flights, and/or other various scraper types. The flight member conveys the sludge via sweeping of the floor to down-stream processes.

Designed and Fabricated according to ASME.

All non-metal sludge collectors are designed and fabricated according to ASME (American Society of Mechanical Engineers) and they are designed, constructed and installed in accordance with the best practices and methods.

Compatibility

The main parts of our product are designed to be easily replaceable and compatible with products made from other manufacturers. For example, simple adaptors make it possible that sprockets can be assembled with various sizes of shaft.

High Quality and Environment-friendly Product.

We manufacture high quality products based on strength, fatigue and wear considerations. We use eco-friendly recyclable engineering plastic, which help promoting harmony between human and nature, saving waste treatment cost as well.

Long Operating Life and Low Maintenance Cost.

Chain and Sprockets are made of material which is non-corrosive and abrasion resistance. In addition, they are designed by technology such as double life type sprocket and save rim. This guarantees long operating life and reduces maintenance cost.

Features

Chain Assembly

Type : NCS720S Pintle type Pitch : 152.4mm material : PET, produced through injection molding Reduction of strength of durability is prevented since the water contents of the resin is zero.

Driven Sprocket

Type : NH78 type PCD : 844.6mm material : LFT-PA, produced through injection molding The driven sprocket can be disassembled into 4 pieces, making maintenance and repair easy. The adaptor can be used by various size so to be installed at any axial diameter.

Head and Idle Sprockets

Type : NCS720S type PCD : 583.1mm(Head), 421.9mm(Idle) material : LFT-PA(body), HDPE(adaptor, sleeve bearing) The sleeve bearing promotes smooth rotation of the sprocket and extends the life expectancy through reducing wearing

Flight assembly

Type E-Fight Size : 150 x 60 mm material : FRP or Aluminum The cross section is E-type that promotes safe transportation of flight against the load exerted by the sludge upon scraping the sedimentation tank floor.B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jin-hwan Oh

- Address

- 303ho Nex-Dong, SKN Technopark, Sangdaewon 1-Dong, Jungwon-Gu, Seongnam-Si, GyongGi-Do, Korea

- Product Category

- Environmental Products,Waste Management,Water Treatment

- No. of Total Employees

- 1-50

- Company introduction

-

English name : Linkon Technology CO. LTD.

Korean name : ㈜ 링콘 테크놀로지

1. Address

- Head Office : 303 Nex-dong, SKn-technopark, 190-1, SangdaewonDong, JoongwonGu, Sungnam-si, Kyongki-do, Korea

- Canada Branch : 25Southvale Drive Vaughan ON Canada L6A 0X2

2. History

- 2009.07 Established Linkon Technology.Co.Ltd

- 2009.10 Established Canada branch office

- 2009.12 Acquired Certification of ISO9001:2008

- 2010.04 Established R&D Center

- 2010.05 Participated in the Exbition (CANECT2010, Toronto, Canada)

- 2012.01 Exports to Mexico - PEMEX (API Oil Separating Sludge Scraper)

- 2012.05 The second registration od Factory

(Munhak-ri 541-1, Jeongnam-myeon, Hwasung-si)

- 2012.05 Trademark application for "Linkon"(canada, Unitted States of America, China)

- 2012.06 Desalination Plant delivery ' Plate Settler & Scraper, Scum Skimmer"3. Supply Records

- 2009.08 Supplied Parts to DEWA co(Finland)

- 2009.08 Supplied and installed Sludge collectors at Daejeon STP (Korea)

- 2010.08 Supplied and installed Sludge collectors at Hwado STP (Korea)

- 2011.11 Due to Supply Parts to Evina water purification plant (Equatorial guinea)

4. Product

- Sludge Collector

- UV Sterilizer

- Sludge Dryer

- Deodorizer

5. Patent

- Utility Patent – 15 items

- Design Patent – 30 items

- Including Sprocket of Chain flight type sludge collector suitable for settling pond for sewage treatment (Registration number : 10-0714061)

- Main Product

Related Products

PVC/Vinyl Wire End Caps

Neoprene Rubber Seal Strip

Granular C5 Petroleum resin for EVA Hot Melt Adhesives

clad steel(Ecoteel)

_2.jpg)

ALUMINIUM PLATE/SHEET/COIL/EXTRUSION (ARCONIC/FUSINA)

South Korea

South Korea