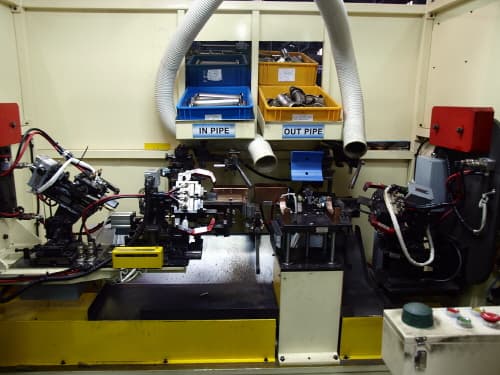

Muffler auto welding assembly cell_1

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- auto welding, muffler, assembly cell, muffler assembly

SKY

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

17

| Product name | Muffler auto welding assembly cell_1 | Certification | - |

|---|---|---|---|

| Category |

Other Vehicle Accessories

Other Machinery & Industry Equipment Exhaust System |

Ingredients | - |

| Keyword | auto welding , muffler , assembly cell , muffler assembly | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

We are a leading manufacturing in the automation welding jig.

These welding celles are auto welding assembly equipment using turn base

with motor.

As you see we offer functional testing, pick and place assemblies, leak

testing, palletized assembly lines and custom material conveying Including

precision functioning, high efficiency, dimensional accuracy, corrosion

resistant as special features.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- SUH YOUNG JU

- Address

- B-402/404, Ulsan Technopark, 421, Daun-dong, Jung-gu, Ulsan

- Product Category

- Other Machinery & Industry Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

We are a leading manufacturing in the automation welding jig.

We have designed & manufactured many customized welding jigs for our clients as per their specification.

All important factors are considered during the design stage.

Full 3d design allows us to accurately visualize complex assemblies in order to evaluate important factors such as torch access, weld spatter protection, robot reach study, ease of loading/unloading, operator safety and future upgrades or additions and so on.

There are a wide assortment of body in white jigs & fixtures.

The assembly items are strictly in compliance with the international industrial standards and are also available as per the customized specifications of the clients.

We are also possible for turnkey projects for various assembly lines.

From simple stand alone manually loaded machines to multi-station cells incorporating auto-load and unload features, these systems have consistently resulted in reduced manufacturing costs and improved product quality.

Typical equipment we offer functional testing, pick and place assemblies, leak testing, palletized assembly lines and custom material conveying Including precision functioning, high efficiency, dimensional accuracy, corrosion resistant as special features.

As well as we supply fabricated components in various industry.

We are furnished with much equipment as well as have rich knowledge and experience. So we are sure of ourself at welding jig area

- Main Markets

-

Japan

Japan

South Korea

South Korea

- Factory Information

-

SKY

- Main Product

Related Products

Spare Parts for Hydraulic Breaker

AIRLESS PUMP- YL 731

Date Pin (Date Core)

,_Smartphone_dryer,_heating_mobile_2.jpg)

Mobile Dryer, Smartphone dryer, heating chamber(RG-202)

QVIA DASH CAM AR790 / FHD Dash Cam / Car DVR / Black Box