Glass color (Glass enamels)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- Category

- Other Paint & Coatings

Shin Ceramic Co., Ltd.

- Verified Certificate

-

17

| Product name | Glass color (Glass enamels) | Certification | - |

|---|---|---|---|

| Category | Other Paint & Coatings | Ingredients | - |

| Keyword | - | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Specifications

Glass colors (Glass enamels)

Glass colors are used for the decoration of glassware such as bottles, tumblers and construction glass. These are not colored glass but designs applied to the surface of the glassware and coated by firing. Glass colors consist of the glass frit (ca. 70~90%) with a low fusing point and the color stain (ca. 10-30%)

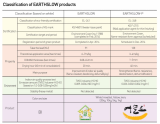

The kinds and the details of Glass color

|

Series

and color |

Firing temp.

(°C) |

C.T.E

(x10-7°C) |

Acid

resistance |

Alkaline

resistance |

Hydrogen

sulfide resistance |

Application

|

|

4000

series |

640-720

|

73~83

|

A

|

A

|

A

|

Architecture & Tempered glass

|

|

5000

series |

620-640

|

78~88

|

A

|

A

|

A

|

Returnable beverage bottles

|

|

7000

series |

580-620

|

65~75

|

B

|

B

|

B

|

Glass dish wares hard glass

|

|

SR7000

series |

560-600

|

78~88

|

C

|

C

|

C

|

Tumbler, Cosmetic bottle

|

|

8000

series |

520-560

|

80~85

|

D

|

D

|

D

|

Lightening glass

Obe-way glass |

The melting point of glass color is approximately 32°C lower than of the ware

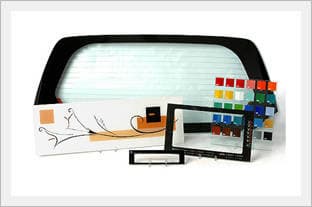

Black pastes for Automobile window glass.

According to working conditions, these can be divided into the laminated glass (front windshield) and the tempered glass (rear window glass) These days, black paste is lead-free.

Details of black paste for automotive window glass

- Black paste for automotive front rear window

- 4708S Lead bearing black paste for windshield

- 4793S Lead bearing black paste for windshield

- 4703 Lead-free black paste for windshield

|

Contents/Paste No.

|

Front Windshield

|

Remarks

|

||

|

4708-S

|

4793S

|

4703

|

||

|

Coefficient of thermal Expansion

(x10-7/°C) |

86.0

|

86.0

|

84.0

|

Dilatometer

|

|

Transition Temp.

(°C) |

410

|

440

|

460

|

Dilatometer

|

|

Softening Temp. of Dilatometer

(°C) |

465

|

495

|

520

|

Dilatometer

|

|

Drying temp.

(°C) |

150

|

150

|

150

|

3min

|

|

Burn out of vehicle

(°C) |

450

|

450

|

450

|

|

|

Firing temp.

(°C) |

550~600

|

580~620

|

580~620

|

|

|

Viscosity(25°C)

|

300

|

300

|

300

|

RION(VT-04)

|

|

On Printing, Medium's addition

|

1-3%

|

1-3%

|

1-3%

|

|

|

Average Particle Size

(μm) |

2.9

|

3.1

|

3.2

|

CILAS1064

|

|

Specific gravity

(g/cc) |

4.2

|

4.0

|

3.9

|

KS M 5131-96

|

|

Phase structure

|

No crystalline

|

No crystalline

|

No crystalline

|

|

|

Lead bearing of Free

|

Bearing

|

Bearing

|

Free

|

|

|

Usage

|

Laminated

|

Laminated

|

Tempered

|

|

- Black paste for automotive front windshield

- 4707 Lead bearing black paste for tempered glass

- 4705M Lead bearing black paste for tempered glass (No crystalline/Anti-stick)

- 4707MB Lead-free black paste for rear window(Crystalline/Anti-stick)

|

Contents/Paste No.

|

Rear window

|

Remarks

|

||

|

4707

|

4705M

|

4707MB

|

||

|

Coefficient of thermal Expansion

(x10-7/°C) |

84.0

|

84.0

|

82.0

|

Dilatometer

|

|

Transition Temp.

(°C) |

440

|

440

|

455

|

Dilatometer

|

|

Softening Temp. of Dilatometer

(°C) |

500

|

540

|

550

|

Dilatometer

|

|

Drying temp.

(°C) |

150

|

150

|

150

|

3min

|

|

Burn out of vehicle

(°C) |

450

|

450

|

450

|

|

|

Firing temp.

(°C) |

680

|

680

|

680

|

|

|

Viscosity(25°C)

|

300

|

300

|

300

|

RION(VT-04)

|

|

On Printing, Medium's addition

|

1-3%

|

1-3%

|

1-3%

|

|

|

Average Particle Size

(μm) |

3.2

|

3.8

|

2.9

|

CILAS 1064

|

|

Specific gravity

(g/cc) |

4.0

|

3.9

|

3.9

|

KS M 5131-96

|

|

Phase structure

|

No Crystalline

|

No Crystalline

|

Crystalline

|

|

|

Lead bearing of Free

|

Bearing

|

Anti-stick

|

Anti-stick

|

|

|

Bearing

|

Free

|

|||

|

Usage

|

Laminated

|

Laminated

|

Tempered

|

|

Conditions of silver paste for automobile glass

|

Contents/Paste No

|

66

|

73

|

80

|

|

Silver

|

66%

|

73%

|

80%

|

|

Flux

|

8%

|

5%

|

3%

|

|

Vehicle

|

26%

|

22%

|

17%

|

|

Viscosity

Rion(VT-04)(ps)22°C |

370±30

|

400±30

|

420±30

|

|

Ohms

|

7.0-8.0Ω

|

5.0-6.0Ω

|

4.0-5.0Ω

|

|

Thick film Thickness

|

6.4μm

|

6.8μm

|

8.7μm

|

|

Thick film width

|

1.00mm

|

1.00mm

|

1.00mm

|

|

Thick film length

|

1.000mm

|

1.000mm

|

1.000mm

|

Silver conductor paste for automobile window glass is designed for use in the heating element of the window glass of the car.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jae-soo Shin

- Address

- CHEOMDAN-RO 303, Danwon-gu, Ansan-si, Gyeonggi-do, Korea

- Product Category

- Other Paint & Coatings

- Year Established

- 1974

- No. of Total Employees

- 1-50

- Company introduction

-

Establishment in 1974, developed Ceramic Colors and Ceramic Materials to localize the materials that used to depend on imports only. By making regular use of ceramic materials, it brought import alternation effects, and by securing soruce of technology, we are exporting products to many countries around the world with competitive powers on quality, cost and technology. Also, the development of environment friendly materials is demanded now a days, and these new materials are used widely for electronics parts such as electronics, Automobiles, PDP, communication parts and etc..

Also, we are doing our best to please our customers wishes by concentrating on developing new products and specially of the products.

- Main Markets

-

China

China

Egypt

Egypt

Indonesia

Indonesia

Malaysia

Malaysia

Pakistan

Pakistan

- Main Product

Related Products

__2.jpg)

119 PRODUCTS SERIES (Automatic fire suppression products)

PUD AUD for coating applications

Architectural Paints

waterpaint

VCI Powder GVP100-B

South Korea

South Korea