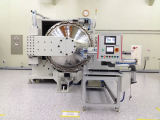

XSG series spin flash drying equipment

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Brand name

- Dongxin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- dryer, drying equipment

- Category

- Drying Equipment

JIANGYIN SUXIN DRYING EQUIPMENT CO.,LTD.

- Country / Year Established

-

China

/

China

/

- Business type

- Others

- Verified Certificate

-

16

| Product name | XSG series spin flash drying equipment | Certification | - |

|---|---|---|---|

| Category | Drying Equipment | Ingredients | - |

| Keyword | dryer , drying equipment | Unit Size | - |

| Brand name | Dongxin | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

Working principle:

With a certain spouted speed, hot-air enters into mixing-grinding dry room from the bottom of drier by inlet pipe. To the materials, a strong wind shear, wind float and spin are forced. So that, the materials turn to be micronized by centrifugal, cutting, collision, friction to strengthen the mass and heat transfer. At the bottom of drier, the larger and wetter cluster of grains are shattered under the action of blender, but the less wet and smaller grains will be carried up by swirling eddy and to be further dried. Because of the rotation flow of gas and solid two phases, and solid-phase has the larger inertia than gas-pahse, the relative speed of them is much larger to strengthen the mass and heat transfer between each other. Therefore the drier has the strong production intensity.

Features:

1. As the materials turn to be micronized by centrifugal, cutting, collision, friction and to be highly decentralized state. Moreover, the larger relative speed of solid-gas two phases has strengthened the mass and heat transfer, this drier has a very strong production intensity.

2. Dry air enters into the bottom of drier and produces a strong rotating flow, so that to wash out the materials on the wall and to eliminate stick phenomenon.

3. At the high-temperature area of the drier bottom, heat-sensitivity materials do not contact with heat surface directly, moreover, it also has equipped with special device to slove the coking and color changed problems of heat-sensitivity materials.

4. Because of the circumferential gas velocity in drier room is higher and the materials stay time is shorter, it can be high-speed, rapid, small equipment and large production.

5. There are elutriate ring and swirl plate on the top of dry room to control the granularity and humidity of outlet materials, so that to achieve the final water granularity requirements of different materials.

Application range:

Organic Compounds: atrazine(agricultural insecticide), cadmium laurate, benzoic acids, benzoic acids, sterilization cinabar, sodium oxalate, cellulose acetate, etc.

Dyes: anthraquinone, black iron oxides, indigoid dyes, butyric acid, titanic hydroxide, zinc sulphide, all kinds of azo dye intermediates.

Inorganic matter: Borax, calcium carbonate, hydroxide, copper sulphate, iron oxide, barium carbonate, antimony trioxide, all kinds of metal hydroxide, all kinds of heavy metallic salt, Synthetic cryolite, etc.

Ceramics: kaolin, silicone trioxide, clay, etc.

Foods: soy protein, gelling strach, lees, triticin, wheat starch, etc.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Dongxin Wu

- Address

- Sihe, Nanjiao Road, Nanzha Town, Jiangyin, Jiangsu, China

- Product Category

- Drying Equipment,Other Machinery & Industry Equipment

- No. of Total Employees

- 101-500

- Company introduction

-

Jiangyin Suxin Drying Equipment Co., Ltd. used to be Jiangyin Dongxin Pharmaceutical Equipment Co.,Ltd. specialized in manufacturing Chinese Medicine extracting, mixing, drying equipment, which are the most advanced in the field. Our company mainly produces extraction concentration units, mesh-belt driers, spin flash driers, spray driers, high-efficiency boiling driers, multi-dimensional motion mixers and so on. Our outstanding quality and thoughtful after-sales service are always highly praised and well received by consumers at home and abroad.

Since ISO9001:2000 standard was carried out, with technical strength, excellent processing technology and strict detection method, all our products have achieved the national industry standards or enterprise standards and are accorded with "GMP" requirements. Moreover, we can offer users the processing design and GMP transformation verification data.

- Factory Information

-

JIANGYIN SUXIN DRYING EQUIPMENT CO.,LTD.

- Main Product

Related Products

Hydrocarbon dry cleaning machine

UV CURING SYSTEM

VCI Paper GVPR100

Autoclave (IR-PC-1600-2000F)

Autoclave-Pressure Cooking Tester/PCT