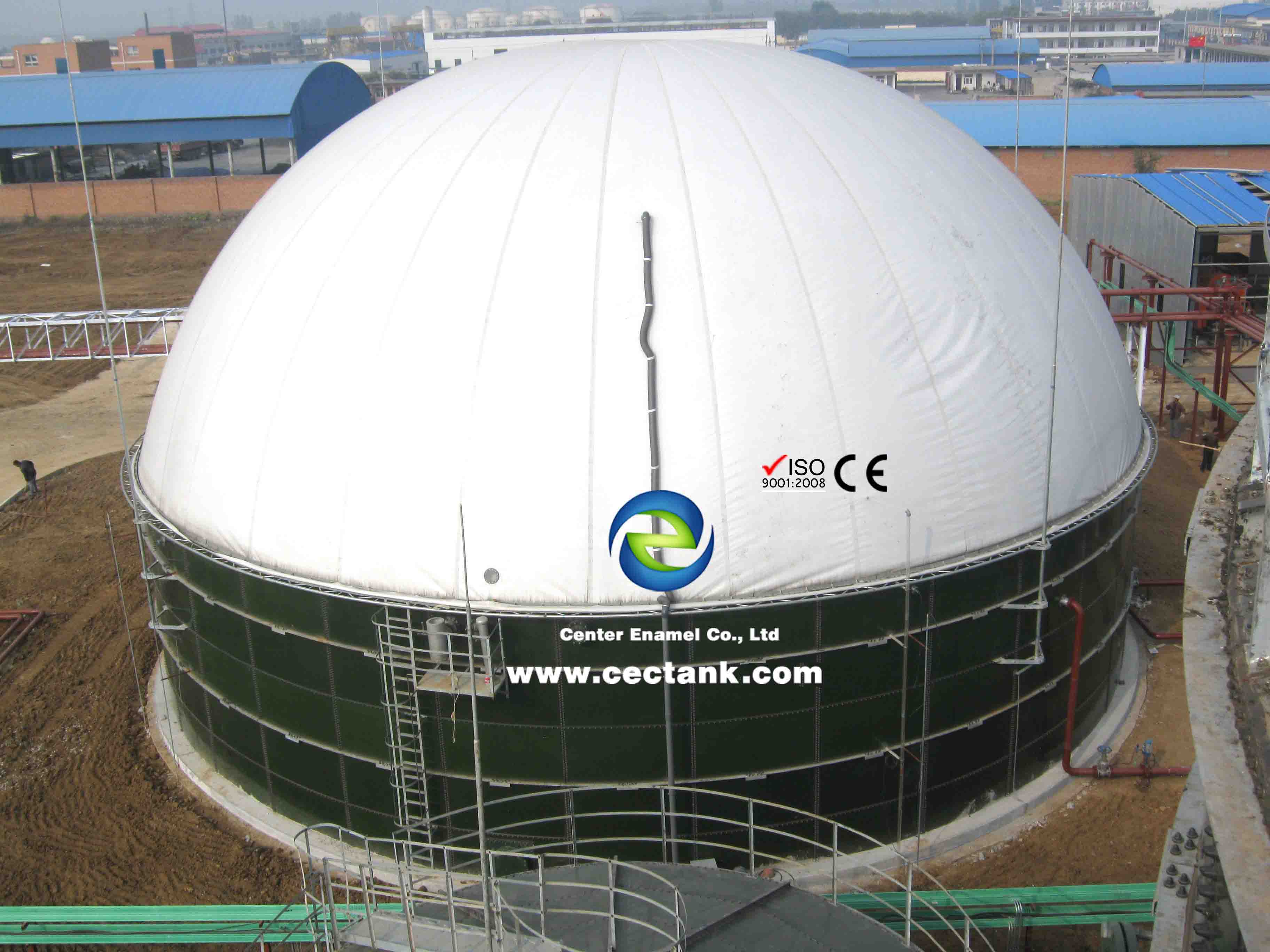

biogas reactor tank equipped with double membrane roof to co

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Center Enamel

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Center Enamel Co., Ltd.

- Verified Certificate

-

5

| Product name | biogas reactor tank equipped with double membrane roof to co | Certification | FDA |

|---|---|---|---|

| Category |

Water Treatment

Other Energy Related Products Other Environmental Products |

Ingredients | - |

| Keyword | biogas digestor , wastewater treatment , treatment tank , storage tank & silo | Unit Size | - |

| Brand name | Center Enamel | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 7309000000 |

Product Information

Center Enamel CO., LTD is the 1st and largest manufacturer in China to produce Enamel tank/ glass-fused-to-steel tank, established in 1989.

Already successfully built more than 2000 enamel steel tanks worldwide, including USA, Australia, Singapore, Maylasia ectc. Beijing Olympics Games sewage treatment project also apply our glass-fused-to-steel tank. Also have our sole distributors in several countries now.

Our tanks comply with international standard like AWWA D103, OSHA, ISO 9001-2015, EN15282 etc.

Now, Our manufacturing facility updated, which is the most advanced facility in China, and match with the world-class manufacturing level. So we have a better control for the coating thickness for each sheet. It's controlled by the automatic machine. The efficiency and accuracy of manufacturing are improved.

Glass-Fused-to-Steel (GFS), also known as Glass-Lined-Steel (GLS) and Biogas Storage Tank , these names all means the same thing. This is the only tank finish where two materials are fused together to achieve the best of both: the strength and flexibility of the steel combined with corrosion resistance of the glass. The high temperature fusion of glass to steel fired at 850°C results in an inert, durable finish. Applied to both interior and exterior, the GFS technology is able to withstand the rigours of the construction site and provide many years of trouble free service in harsh environments.

Double membrane gas storage tank that is roof mounted on an existing tank, consists of an external membrane which forms the outer shape, and an internal membrane which seals the digester gas-tight.

Enamel tank are the ideal solution for a large number of applications, some are listed below:

- Potable water/drinking water

- Slurry

- Industrial effluent

- Bulk materials / as silo

- Sewage treatment

- Biogas digesters

- Process water

- Reverse osmosis

- Fire water

- Over 30 year lifespan

- Short construction period

- Superior corrosion resistance, service life is more than30 years

- Low project cost

- Tank volume can be easily expanded

- Beautiful appearance, color can be customized

- No need big installation equipment

- Easily expanded, dismantled, moved

Center Enamel CO., LTD is able to provide

1. Tank Erection: sending our supervisors to guide the installation work.

2. A turnkey project services from design, drawings, installation.

3. Quality insurance of over 30 years. 3 years free quality guarantee after installation finished.

4. Nice after-sale service, any problems will get our prompt response.

Tank Installation

Production line

Category | Specification |

Coating Color | Dark green, white, blue, color can be customized |

Coating Thickness | 0.25~0.40mm ,double coating |

Acid and alkalinity proof | Standard sheet PH:3~11 |

Adhesion | 3,450 N/cm |

Elastic | Same as steel sheet,around 500 KN /mm |

Hardness | 6.0 ( Mohs ) |

Service life | ≥30Years |

Holiday test | >1500v |

Permeability | Gas / liquid impermeable |

Easy to clean | Smooth, glossy, inert, non adhesive |

Corrosion resistance | Excellent,suitable for wastewater, salt water, sea water, high-sulfur crude oil, salt fox, organic and inorganic compounds |

Volume | 18-25400 cubic meters |

- Verified Certificate

-

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Ding Wenzhan

- Address

- No.139, Fuxi Street, Zhengding County Shijiazhuang 050000 CHINA

- Product Category

- Other General Industrial Equipment

- Year Established

- 1989

- Company introduction

-

Center Enamel Co, Ltd (Shijiazhuang Zhengzhong Technology Co, Ltd) is a professional manufacturer dedicated to the design and fabrication of industrial and household enameled products since 1989. Our products range from Glass-Fused-to-Steel tanks to enameled cookware, enameled bathtubs and enamel glaze with a professional staff of enameling R&D team and more than 20 enameling patents.

Center Enamel Co., Ltd is not only the first Glass-Fused-to-Steel tanks manufacturer and supplier in China, but also the most experienced Glass-Fused-to-Steel tanks manufacturer in all of Asia. Center Enamel Glass-Fused-to-Steel tanks engineering & design, product testing and quality system are in strict accordance with ISO 9001-2015, AWWA D103-09, OSHA, ISO/EN 28765, NSF61 and NFPA etc. international standards. GFS/GLS bolted tanks are wildly used in drinking/potable water, industrial effluents, municipal sewage, bio-energy, landfill leachate, agriculture etc applications. Until 2018, Center Enamel Glass-Fused-to-Steel tanks have been exported to more than 45 countries including USA, Australia, Canada, Malaysia, Indonesia, Russia, UAE, Panama, India and South Africa etc. The superior product quality and prompt service gain us worldwide recognition.

- Main Markets

-

Australia

Australia

Brazil

Brazil

Indonesia

Indonesia

Malaysia

Malaysia

Mexico

Mexico

Panama

Panama

Philippines

Philippines

Singapore

Singapore

Thailand

Thailand

U.S.A

U.S.A

- Factory Information

-

Shijiazhuang Zhengzhong technology Co., Ltd

- Main Product

China

China

_2.png)

_2.png)