PP, PE Synthetic Resin

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Industrial Supplies , Coating & Paint , PP

Serom ENG Co., LTd.

- Verified Certificate

-

11

| Product name | PP, PE Synthetic Resin | Certification | - |

|---|---|---|---|

| Category |

Industrial Supplies

Coating & Paint PP |

Ingredients | - |

| Keyword | plastic , chemical , hdpe , pe , pipe , pp , synthetic resin | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | Stock | - | |

| Supply type | - | HS code | - |

Product Information

PP, PE Synthetic Resin

|

HDPE

|

Red (SR-01)

|

purpose

|

(Box, pallet, contaniner...etc)

Injection molding |

|

Green (SR-02)

|

|||

|

Black (SR-03)

|

|||

|

Black (PB-01)

|

purpose

|

(Pipe, sheet...etc)

extrusion molding |

|

|

Sky Blue (PSB-02)

|

|||

|

White (PN-03)

|

|||

|

LDPE

|

Black (PB-04)

|

purpose

|

(Pipe, sheet...etc)

extrusion molding |

|

PP

|

Yellow (YL-05)

|

purpose

|

extrusion molding injection molding

|

|

Green (GR-06)

|

|||

|

Black (BL-07)

|

|||

|

Red (RD-08)

|

│Application│

>> Pipe

- The Resin Electric Pipe

- Polyethylene Underground Electric Pipe

- Trans Type of High Pressure Perforated & Slotted Pipe

- High Densty Polyethylene Water Service Pipe

- Double-Wall Polyethylene Pipe

>> Plastic

- Foomed Building Materials

- Foamed Frame

- P.P Band

- P.P, PE Plastic

│Physical Properties│

[PE]

>> Physical And Chemical Properties

- APPEARANCE : Circular solid with white, light Yellow

- ORDOR : Not Applicable

- PH : Not Applicable

- SOLVENT SOLUBILTY : Hot decalin, Hot tetrahydronaphthalene, Hot tetrachloroeth

- SOLUBILTY IN WATER : Not Applicable

- BOILING POINT/BOILING POINT RANGE : Not applicable

- MELTING POINT/MELTING POINT PRNGE : 130~170˚C

- EXPLOSIVENESS : Not Applicable

- THE EXTENT OF OXIDATION : Not Applicable

- VAPOR PRESSURE : Not Applicable

- SPECIPIC GRAVITY (WATER=1.0) : 0.89~0.91

- COEFFICIENT OF DISTRUIBUTION : Not Applicable

- VAPOR DENSITY (WATER=1.0) : Not Applicable

- VISCOSITY : >1.30

- MOLECULAR WEIGHT : >40,000

>> Stability And Reactivity

- CHEMICAL STABILITY : Stable in room temperatures and pressure

- CONDITIONS TO AVOID

- Heat (Temperatures over 650 f), Flams, sparks and other sources of ignition.

- Avoid contact and storage with strong oxidizing agent - MATERIAL TO AVOID (INCOMPATAVILITY)

- Strong oxidizer

- Peroxides - HAZARD MATERIALS IN DECOMPOSITION : Thermal decomposition products, miscellaneous decomposition products

- HAZARD POLYMERIZATION : Will not polymerize

>> Disposal Considerations

- RECULATORY STATE

- Dispose in accordance with all regulations of central government and local autonomous entity - DISPOSAL METHOD : Not Applicable

>> Regulatory Information

- LAW FOR KOREA INDUSTRIAL SAFETY AND HEALTH CORPORATION : Not Applicable

- HAZARD CHEMICAL MATERIALS ADMINISTRATION LAW : Not Applicable

- THE FIRE SERVICES ACT : Not Applicable

- TSCA INVENTORY STATUS : Prescribed

- TSCA 12(b) EXPORT NOTIFICATION : Not listed

- CERCLA SECTION 103 (40CFR302.4) : Not Applicable

- SARA SECTION 302 (40CFR355.30) : Not Applicable

- SARA SECTION 304 (40CFR355.40) : Not Applicable

- SARA SECTION 313 (40CFR372.65) : Not Applicable

- SARA HAZARD CATEGORIES, SARA SECTION 311/312 (40CFR370,21) :

- ACUTE : N/A

- CHRONIC : N/A

- FIRE : N/A

- REACTIVITY : N/A

- SUDDEN RELEASE : N/A - OSHA PROCESS SAFETY (29CFR1910.119) : Not Applicable

- CALIFORNIA PROPOSITION 65 : Not Applicable

- EC NUMBER : Not Applicable

>> Physical And Chemical Properties

|

Test Conducted

|

Test Results

|

|

|

1

|

Tensile Test (KSM 3006 A-type)

|

|

|

Tensile Strength (kgf/cm²)

|

247.2±3.7

|

|

|

Tensile Modulus (kgf/cm²)

|

6,656.9±331

|

|

|

Break % Strain (%)

|

271.8±40

|

|

|

Toughness (kgf/cm²)

|

514.1±85.3

|

|

|

2

|

Flexural Test (KSM 3008)

|

|

|

Flexural strength (kgf/cm²)

|

233.4±15.2

|

|

|

Flexural Modulus (kgf/cm²)

|

7.918.0±495

|

|

|

3

|

Izod Impact Strengh Test (KSM 3055)

|

|

|

Izod Impact strength (kgf.cm/cm²)

|

15.9±1.0

|

|

|

4

|

Density Test

|

0.93-0.94

|

[PP]

>> Physical And Chemical Properties

|

Test Conducted

|

Test Results

|

|

|

1

|

Tensile Test (KSM 3006 A-type)

|

|

|

Tensile Strength (kgf/cm²)

|

274.8±3.97

|

|

|

Tensile Modulus (kgf/cm²)

|

8,207.5±479.7

|

|

|

Break % Strain (%)

|

42.3±7.9

|

|

|

Toughness (kgf/cm²)

|

87.7±29.0

|

|

|

2

|

Flexural Test (KSM 3008)

|

|

|

Flexural strength (kgf/cm²)

|

368.9±3.8

|

|

|

Flexural Modulus (kgf/cm²)

|

7.333.1±241.7

|

|

|

3

|

Izod Impact Strengh Test (KSM 3055)

|

|

|

Izod Impact strength (kgf.cm/cm²)

|

5.65±0.37

|

|

|

4

|

Density Test

|

0.94-0.95

|

* Note

- Number of Specimens (EA) : Tensile Test 10 EA, Flexural Test 5 EA, impact Strength Test 5 EA

- Tensile Test cross head speed : 50mm/min

- Flexural Test Cross head speed : 2.5mm/min

>> Physical And Chemical Properties

|

Description

|

These are indicative values only.

Please refer also to the product specification sheet. |

|

Physical state

|

Solid (translucent to white pellets)

|

|

ODOR

|

Slight waxy odor

|

|

Molecular Weight

|

NOT available

|

|

Boiling Point Range

|

NOT available

|

|

Freezing Point

|

NOT available

|

|

Melting Point

|

130-170˚C

|

|

Autoignition Temperature

|

>350˚C

|

|

Flash Point

|

>340˚C

|

|

Vapor Pressure

|

NOT available

|

|

Specific Gravity (water=1)

|

0.89-0.92

|

|

Water Solubility

|

Insoluble

|

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Young Gi Yoo

- Address

- 39, Nonhyeon-ro 46beon-gil, Namdong-gu, Incheon, Korea

- Product Category

- Coating & Paint,Industrial Supplies

- No. of Total Employees

- 51-100

- Company introduction

-

We are Korea professional manufacture all kinds of HDPE,PP,PE synthetic Resin for reproducted Raw materials as followings using purpose are;

-Re-Pro,HDPE,PE, used extrusion in factorys made for pipe of drain/Underground,Electric with trans of high pressure perforated and Slotted pipe & plate,Frame,Others.

-Re-Pro,PP used injection in factoried made for General Homeware,Chair/Furniture,Toys/Weel,Metal of construction/Container,Bucket Etc...

We can be made recycle of HDPE,PE,PP accordance of clients wants to made goods with option that had been commended at nowadays from clients.

We come domestic and oversea clients to cooperative always with us.We shall very appreciate hearing favorable an early yours as bellow by E-mail or Fax and Call and then response immiediately.

Sincerely yours,

- Factory Information

-

Serom Chemical Industry

- Main Product

Related Products

Granular C5 Petroleum resin for EVA Hot Melt Adhesives

CARBON STEEL, STAINLESS STEEL, DUPLEX PLATE

Brushed PET film, Brushed foil, Hairline, laminating, VCM

DETDA(Diethyl toluene diamine) Polyurea curing agent

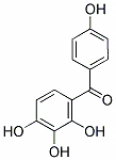

2,3,4,4'-Tetrehydroxybenzophenone, CAS NO.: 31127-54-5

South Korea

South Korea