Plasticizer

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- plastic additives, piasticizer, non-phthalate

- Category

- Catalyst & Chemical Auxiliaries

COS Chem

- Verified Certificate

-

9

| Product name | Plasticizer | Certification | - |

|---|---|---|---|

| Category | Catalyst & Chemical Auxiliaries | Ingredients | - |

| Keyword | plastic additives , piasticizer , non-phthalate | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

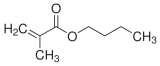

Plasticizer

│ What is Plasticizer? │

Plasticizers are defined as materials that, when added to a polymer, cause an increase in flexibility and workability. Well over 90% of plasticizer sales are to the PVC industry. The reason for this high concentration of sales is that the benefits provided by plasticization of PVC are far greater than those imparted to other polymers. Without the wide range of additives available (e.g., plasticizers, stabilizers, fillers, lubricants, and pigments), PVC would be of little use. The development of PVC as a commodity polymer is linked to the development of its additives.

│ Types Of Plasticizers │

The most widely used products are phthalic anhydride esters, accounting for about 70% of plasticizer production in the U.S. The type of phthalate leading in consumption is dioctyl ester (DOP), followed di-isononyl (DINP), di-isodecyl (DIOP), and smaller amounts of other phthalate esters dibutyl (DBP) and benzyl butyl (BBP). In each case, these materials are phthalate esters of alcohols of varying chain length. There are about 10 phthalate esters used commercially.

The widespread use of phthalates is a reflection of their all-round plasticizing performance and their provision of adequate properties for many standard products. They possess reasonable plasticizing efficiency, fusion rate, and viscosity. Phthalates are at the lower end of the price range of the total family of plasticizers, which adds to their popularity.

The next most widely used plasticizers are esters of adipic acid. The alcohols used to make the adipates are similar to those used to make the phthalates. Dioctyl adipate (DOA) is made in the greatest quantity, followed by ditridecyl (DTDP). There also are about eight other adipate esters manufactured.

The family of adipic acid esters in PVC applications has improved low-temperature performance relative to phthalates.

The principle advantage of phosphate esters is improved fire retardancy relative to phthalates and other hydrocarbon-based plasticizers. The main applications are in wire and cable. The types of phosphates made are tris(2-ethyl), tris(2-phenyl), and isodecyl diphenyl phosphates.

Following the adipates in order of production are epoxidized esters. Nearly all of these are epoxidized soybean oil (ESBO). ESBO serves both as a lubricant and as a secondary stabilizer due to its epoxy content, which can remove hydrochloric acid (HCI) from the degrading polymer.

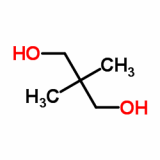

In addition to the phthalates, adipates, and epoxies, there are a wide variety of other plasticizer types. Trimellitic esters are made from trimellitic anhydride and an alcohol, usually 2-ethyl hexanol. The principal features of these esters, when processed with PVC, are their low volatility. Consequently, large volumes of trimellitic esters are used in high-specification electrical cable and sheathing. The low-volatile-loss figure also serves well in automotive interior applications where the issue of windshield fogging is important. Polyester plasticizers are high-molecular-weight compounds, usually made from butanediols and adipic acid. These polymeric compounds have exceedingly low volatility and high resistance to chemical extraction. They are often found in medical products, such as blood tubing or wound coverings.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Alex Kim

- Address

- (Siksadong, Dongguk Univ. Industrial-Academic BLDG.) No. 324, Dongguk-Ro 32, ILsandong-Gu, Goyang-Si, Gyunggi-Do, Korea

- Product Category

- Coating & Paint,PP,PVC,Plastic Raw Materials

- Year Established

- 2015

- No. of Total Employees

- 1-50

- Company introduction

-

<p>COS CHEM as a agent of LG CHEM under the goal of becomming global plastic export company started its business in 2015. With our main products; PVC Stabilizer, AA, PE, PP, PVC, ABS, PS, Recycled Resin(PE, PP, EVA) and PVC plasticizer and PVC & PET sheet. We are now mainly doing business with Indian and Chinese plastic company and trying to expand our market all over the world.

Alex Kim who had worked as a main member of LG Chem has abundant experience about plastic market and business. And had put the all the know-how into COS Chem.

Currently, COS CHEM is co-operating with LG Chem, Woochang Chem, KP Tech. We would like to provide our customers the best bridge to the broad market of Korean plastic.

- Main Markets

-

China

China

India

India

Myanmar

Myanmar

Viet Nam

Viet Nam

- Main Product

Related Products

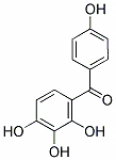

2,3,4,4'-Tetrehydroxybenzophenone, CAS NO.: 31127-54-5

VCI Desiccant GVD300

adult diaper

Corn Cob Meal

glucolactone/Glucono-δ-lactone(GDL)

South Korea

South Korea