Injection molding machine for LSR, Vertical LSR Injector

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- L/C

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- liquid silicon rubber, lsr, lsr injector, lsr moulding

- Category

- Molds , Plastic Product Making Machinery

i-SSAN Engineering

- Membership

- PRO

- Recent Visit

- Oct 10, 2024

- Country / Year Established

-

South Korea

/

2018

South Korea

/

2018

- Business type

- Manufacturer

- Verified Certificate

-

12

| Product name | Injection molding machine for LSR, Vertical LSR Injector | Certification | - |

|---|---|---|---|

| Category |

Molds

Plastic Product Making Machinery |

Ingredients | - |

| Keyword | liquid silicon rubber , lsr , lsr injector , lsr moulding | Unit Size | 2000.0 * 2500.0 * 2000.0 mm |

| Brand name | - | Unit Weigh | 800 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

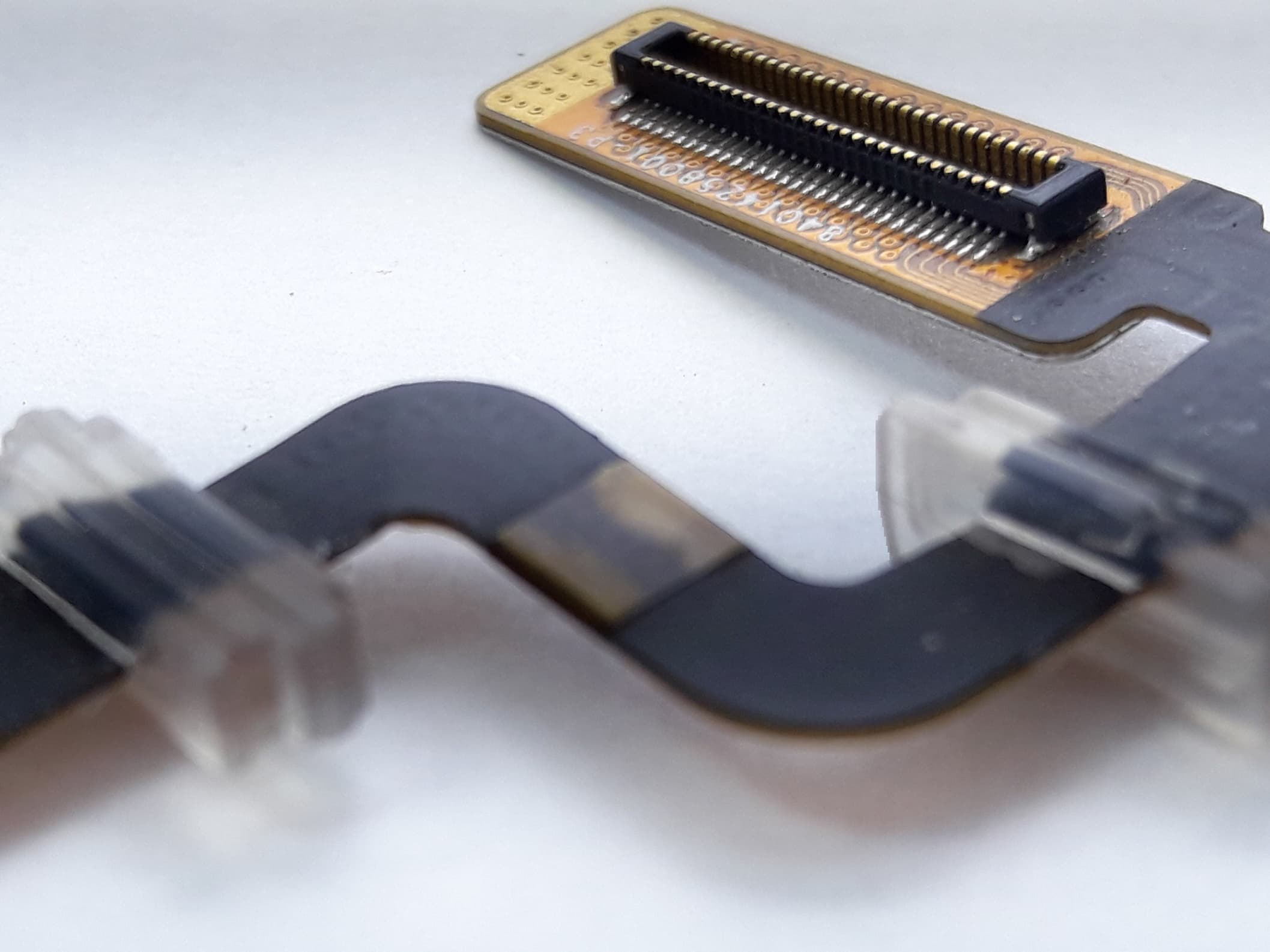

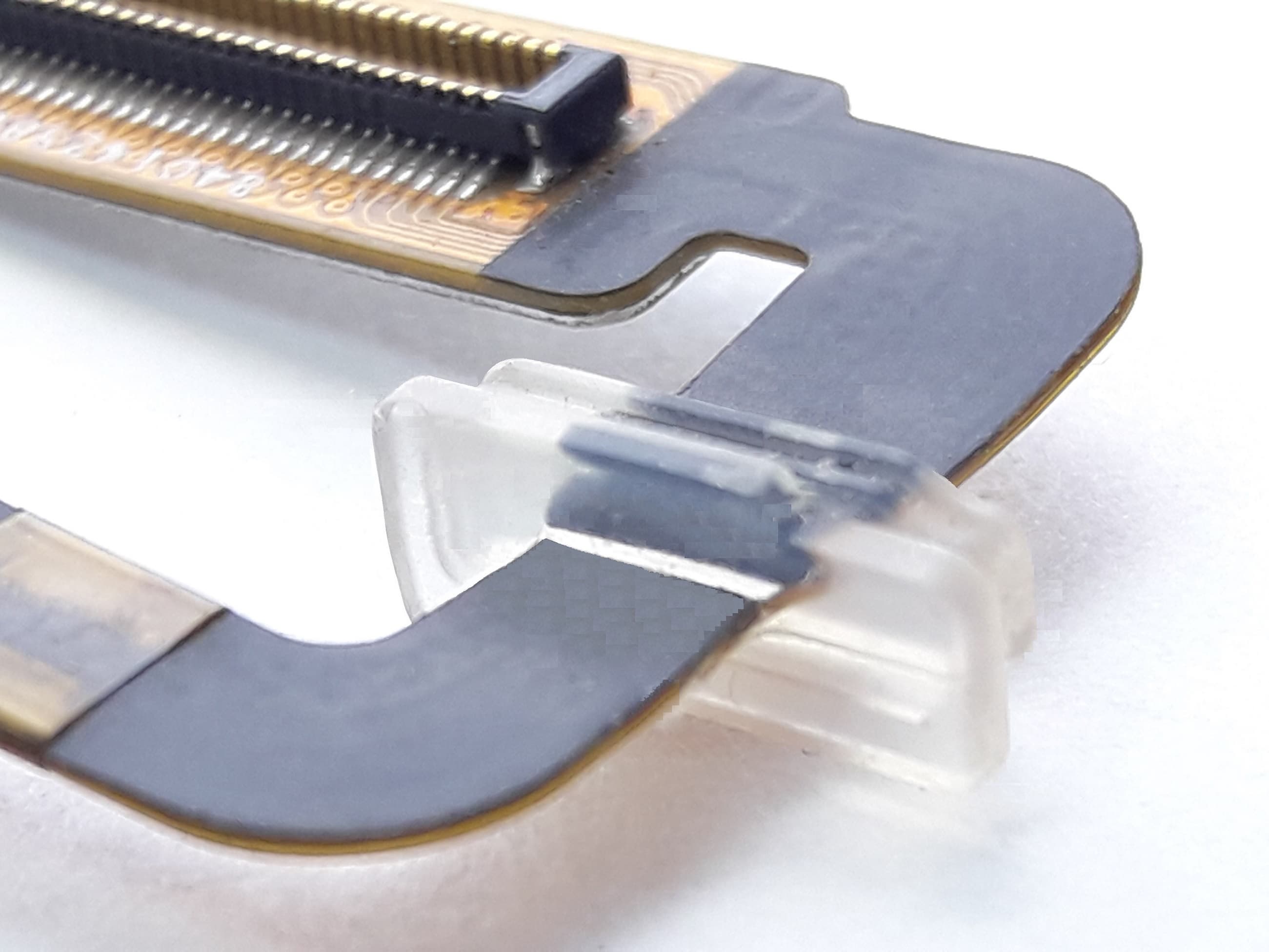

Model: VHSi-030 30cc, Vertical LSR Injector

This LSR injection molding machine is vertical type.

Usually used for Insert molding process.

Injector and Dosing unit are separated but installed

very close each other.

Machines are Lined up according to the molding situation.

All of machines can be supplied according to the client's requirements.

Compact and easy moving by cater.

① General purposed LSR Injection machine (injection volume 30 ~ 3000cc)

② Injector and Dosing is separated but Very Close located.

③ Compact size

④ Moving by caster, location is not limited-various combination assembling

⑤ Recommended for Insert molding process.

⑥ All utilites are embeded in machine.

⑦ Controlled by Touch screen interface.

⑧ Check nozzle installed

⑨ Perging Device is optional

⑩ Injection Volume, Machine size, Mold size is depeding on client's requirements.

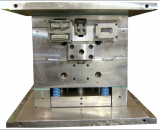

Model: VHSi series

Injection Volume: Min 30cc ~ max 3000cc

Dosing Volume Below 500cc 20Liter x 2

Over 1000cc 200Liter x 2

Machine Compact but depending on Molded part's shape & size

Nozzle type Check Nozzle type

Drive source Hydraulic

Dosing drive Pneumatic, Hydraulic, Servo motor

Utilities Embeded mold heater control

Embeded nozzle chiller

Options Purging device

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C | Shipping time | Negotiable |

- President

- Minho Kim

- Address

- 356-10, Hwaseong-si, Gyeonggi-do, Korea

- Product Category

- Medical Consumables,Molds,Other Rubber Products,Plastic & Rubber Machinery Parts,Plastic Product Making Machinery

- Year Established

- 2018

- No. of Total Employees

- 1-50

- Company introduction

-

Business Scope

▷ Mold making

▷ Injection & Extrusion equipments

▷ Automation

▷ R&D

▷ Plant, System Engineering

Business Items

Machineries, Tools, Special Equipments that we make;

① Plastic Injection Molding machines

② LSR Injection molding Machines

③ PIM machineries (with related material handling equipments)

④ CNC Injection molding machines ( Full Automation )

⑤ Special Injection molding machine (LED, Slipring, Relay Connector)

⑥ Extruder,

⑦ Automatic Injecton Molding system

⑧ Specilized/Customized for Ultra Micro & Precision Injection molding sysm.

(LSR, Artificial Eyeball)

Software Service:

Design & Developing manufacturing process of New Materials related

with Injection, extrusion and press technologies.

① New materials of Polymers

② Nano- Powders (Metal, Ceramic),

③ Liquid Silicon Rubber(LSR)

Engineering consulting:

① Part design & Modeling (2D, 3D),

② Process Developing,

③ Plant Engineering.,

Mold Making Service(Specialized)

① Plastic Mold,

② PIM, PICM, PIM2K, PICM2K (Functional Mold for PIM)

③ LSR Mold

Special System (Micro Plant)

① Automatic LED module production system,

② Automatic Relay connector insert molding system,

③ Surgical Anchor (Screw) production system (Biodegradable resign),

④ Artificial Eyeball parts (LSR),

⑤ CNC Injection molding machine.

Special Producing items

① Medical Comsumables : Sutute Anchor (Peek & Biodegradable materials)

② Artificial Organ : Artificial blood vessel (Teflon)

: Artificial Eyeball (LSR)

③ Menstrual Cup (LSR)

④ Industrial Parts

⑤ Cushiion seat of Egg tray(LSR)

- Main Markets

-

South Korea

South Korea

- Factory Information

-

I-SSAN ENGINEERING

- Main Product