Nano Disperser (High Pressure Homogenizer)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- Nano Disperser (High Pressure Homogenizer)

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

Ilshin Auto Clave Co., Ltd.

- Country / Year Established

-

South Korea

/

South Korea

/

- Business type

- Others

- Verified Certificate

-

15

| Product name | Nano Disperser (High Pressure Homogenizer) | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | high pressure homogenizer , homomixer , nanodisperser , nano disperser | Unit Size | 100.0 * 100.0 * 100.0 mm |

| Brand name | Nano Disperser (High Pressure Homogenizer) | Unit Weigh | 100 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

When material(Fluid) is passed orifice module under ultra high pressure condition, supersonics speed is formed by a rapid decrease in pressure. At this very moment, the material can be cell destruction, atomization, emulsion, dispersion, and liposome by impact, cavitation and turbulence shear stress of particle. Comparing with general homogenizer, Nano Disperser is more efficient and widely used in areas of chemical, food, cosmetics, petroleum and paints.

Nano Disperser is Ilshin Autoclave Co.,Ltd's brand of high pressure homogenizer. "Nano" is abbreviation of Nano Technology, and "Disperser" means homogenizer. Fluid passes through orifice module and then shear, carvitation and impact will occur.

Dispersion

When different types of materials are mixed, the mixture becomes a homogenized state through particle breakage. This technology is applied in industries such as chemistry, cosmetics, food, biology and electronics. There are two types of dispersion according to the material : Suspension & Emulsion

Suspension Disperse solid as powder to liquid - Paint, Ink etc.

Emulsion Dispersion between liquid and liquid such as water and oil which cannot be mixed

- Milk, Water, Oil etc.

Comparison chat of high pressure dispersion and other dispersion methods

Flow rate at different pressure

Pressure(Bar) 500 1000 1500 2000 2500

Flow rate(m/sec) 313 442 542 626 700

Nano Disperser

Interaction Chamber Type

* Various application according to material of orifice

- Diamond, ceramic etc.

* Proper orifice size is important

- According to product, demanded output

Intensifier Pump

* Seal's durability

* Plunger's anti-abrasion

* Cylinder's safety design

Pump head stress analysis comparison

Safety is paramount for Ilshin's equipment. Ilshin always takes account of safety from design to manufacture. The picture above shows the momentary Max. stress value while plunger working. In order to decrease the Max. stress value, Ilshin changes the structure and material to disperse the stress concentration and ensure safety.

Nano Disperser (High Pressure Homogenizer)

When material(Fluid) is passed orifice module under ultra high pressure condition, supersonics speed is formed by a rapid decrease in pressure. At this very moment, the material can be cell destruction, atomization, emulsion, dispersion, and liposome by impact, cavitation and turbulence shear stress of particle. Comparing with general homogenizer, Nano Disperser is more efficient and widely used in areas of chemical, food, cosmetics, petroleum and paints.

NLM 100 is a type of high pressure homogenizer, which Max. Pressure is 20,000psi and flow rate is 100ml/min. It works by motor and 220V electricity power easily. PCB and speed controller is installed to adjust the motor speed and flow. There is backstay and handle to make operation easily. Also, Air Vent Valve in head to release air can make input simply. Chamber Type and size can be changed according to specimen and it is very easy to change specimen and clean inner parts.

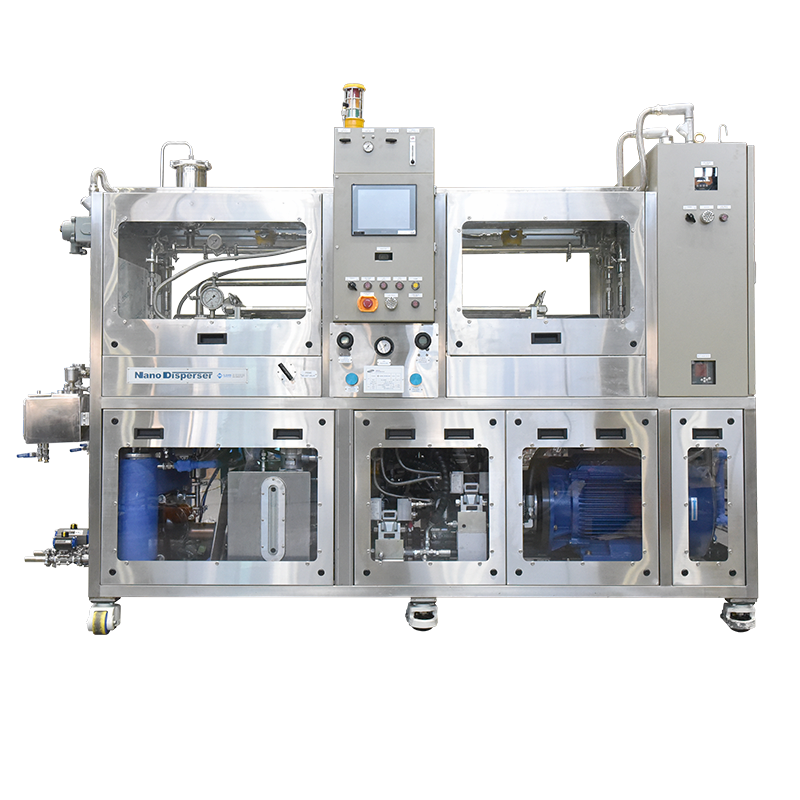

NH 500 is a type with 5Hp hydraulic pressure system and Max. Pressure is 40,000psi and flow rate is 0.5ℓ /min. It designed with careful consideration of safety and convenience. There is case in driving part that can be opened or closed easily. It works with hydraulic pressure system and installs inner cooling system that make sure continuous working. It consists with the first Interaction Chamber and the second Back Pressure Chamber which can prevent linear dispersion and re-cohesion of reactant. Most of the construction is stainless steel with strong corrosion resistance. Taking account of inner specimen and chemical reaction, multiple materials (PEEK, UHMWPE, PTFE) are used to make sure the durability. Also, there are many options according to Back Flashing or Explosion-proof construction

NH 2000 is a type with Max.25Hp hydraulic pressure system and Max. Pressure is 40,000psi and flow rate is 2ℓ /min. It is a production scale which Max. flow rate reaches 120ℓ each hour. It designed with careful consideration of safety and convenience. It works with hydraulic pressure system and installs inner cooling system that make sure continuous working. It consists with the first Interaction Chamber and the second Back Pressure Chamber which can prevent linear dispersion and re-cohesion of reactant. Most of the construction is stainless steel with strong corrosion resistance. Taking account of inner specimen and chemical reaction, multiple materials (PEEK, UHMWPE, PTFE) are used to make sure the durability. Also, there are many options according to Back Flashing or Explosion-proof construction

NH4000 is a type with Max.50Hp hydraulic pressure system and Max. Pressure is 40,000psi and flow rate is 4ℓ /min. It is production scale which Max. flow rate reaches 240ℓ each hour. It designed with careful consideration of safety and convenience. It works with hydraulic pressure system and installs inner cooling system that make sure continuous working. It consists with the first Interaction Chamber and the second Back Pressure Chamber which can prevent linear dispersion and re-cohesion of reactant. Most of the construction is stainless steel with strong corrosion resistance. Taking account of inner specimen and chemical reaction, multiple materials (PEEK, UHMWPE, PTFE) are used to make sure the durability. Also, there are many options according to Back Flashing or Explosion-proof construction.

NH8000 is a type with Max.75Hp hydraulic pressure system and Max. Pressure is 40,000psi and flow rate is 8ℓ /min. It designed with careful consideration of safety and convenience. It works with hydraulic pressure system and installs inner cooling system that make sure continuous working. It consists with the first Interaction Chamber and the second Back Pressure Chamber which can prevent linear dispersion and re-cohesion of reactant. Most of the construction is stainless steel with strong corrosion resistance. Taking account of inner specimen and chemical reaction, multiple materials (PEEK, UHMWPE, PTFE) are used to make sure the durability. Also, there are many options according to Back Flashing or Explosion-proof construction.

Contact Person

Kim Hyun Hyo

Company

ILSHINAUTOCLAVE.CO.,Ltd

Address

835 Taplipdong, Yuseonggu Daejeon (Techno valley)

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Hyun Hyo Kim

- Address

- 1688-15 , Sinil-dong Daedeok-gu Daejeon

- Product Category

- Other Machinery & Industry Equipment

- No. of Total Employees

- 1-50

- Company introduction

-

Ilshin Autoclave Co, Ltd is a lead company in manufacturing high pressure/high temperature applications equipments including supercritical fluid systems, reactor, vessels/PRV (pressure regulating valves), isostatic press, hot press, metering pumps, agitator and hydrothermal synthesis equipments etc for the purpose of pilot production and industrial plant scale.

- Main Product

Related Products

Korean children's clothing chichikaka brand

Marine Loading Arm

Spare Parts for Hydraulic Breaker

Portable line boring machine, Elsa Supercombinata EASY Compact

Date Pin (Date Core)